- Joined

- Jun 29, 2014

- Messages

- 4,059

I hope this makes sense. I have a chucker headstock with a 5C collet taper and threaded nose.

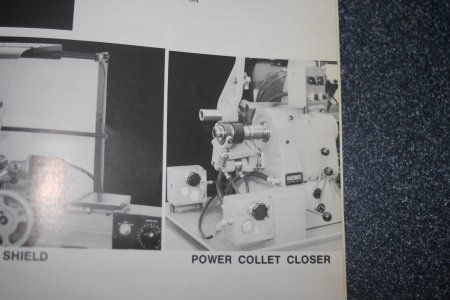

I want to have the option of bar feeding on this. This means an air collet on the back of the headstock (Dunham Tool) or something similar up on the nose.

A third option is to put a cylinder on the lever arm. I'm open to any and all options really, but the point is that I want this to happen automatically.

As I'm looking around the interwebs, I'm realizing I don't really think there is a good option for a nose mounted air collet for the style of spindle nose I have. As I continue looking, I realize I don't know what the industry standard name is for my spindle type. I see A5, A6, D1, D2, etc. (I'm sure I'm getting all of that wrong) but I don't know if mine is one of those or something else. I suspect something else, so I feel like I'm wasting time for something I'm unfamiliar with.

Hardinge experts, the question I have is: does the design allow for an air collet closer on the spindle nose with the style of spindle I have? If so, how is the spindle nose locked and clocked with the collet closer for reverse rotation? Or is the clamping pressure enough to do that? And if I'm correct in all of that, what do you call this spindle type?

I want to have the option of bar feeding on this. This means an air collet on the back of the headstock (Dunham Tool) or something similar up on the nose.

A third option is to put a cylinder on the lever arm. I'm open to any and all options really, but the point is that I want this to happen automatically.

As I'm looking around the interwebs, I'm realizing I don't really think there is a good option for a nose mounted air collet for the style of spindle nose I have. As I continue looking, I realize I don't know what the industry standard name is for my spindle type. I see A5, A6, D1, D2, etc. (I'm sure I'm getting all of that wrong) but I don't know if mine is one of those or something else. I suspect something else, so I feel like I'm wasting time for something I'm unfamiliar with.

Hardinge experts, the question I have is: does the design allow for an air collet closer on the spindle nose with the style of spindle I have? If so, how is the spindle nose locked and clocked with the collet closer for reverse rotation? Or is the clamping pressure enough to do that? And if I'm correct in all of that, what do you call this spindle type?