Hello everyone,

Some news after these almost 2 weeks of absence. Here is the progress of the work:

- Dismantling of the spindle, the variable pulley, the variable pulley frame and the advance box,

- Dismantling of the steering wheel of the saddle for painting the steering wheel and the block,

- Change of the needle bearings of the saddle steering wheel (one of the 2 had the needles completely broken),

- Disassembly / cleaning / inspection of the small flywheels of the transverse and upper carriages

- Repair of 2 bakelite parts with black-dyed epoxy resin (here in photo before sanding),

- Dismantling of the doors, interior painting and cleaning / bluing of the clamp storage shelves,

- Thorough cleaning of the variable pulley,

- Changing the bearings of the variable pulley,

- Repair of the variable pulley by brazing (the internal axis of the pulley was no longer attached to the pulley),

- Repair of the crack on the cast iron frame by adding a "U" welded iron, gluing with charged epoxy, fixing by drilling / tapping H M10 screws (sorry not really a photo, I was too focused ,

- Change of the variable belts which in particular required the lowering of the engine block by ten centimeters because the previous owner had installed belts that were too short (and also too wide),

- Reassembly of the assembly,

Now it remains to adjust the assembly (alignment, belt tension, etc.).

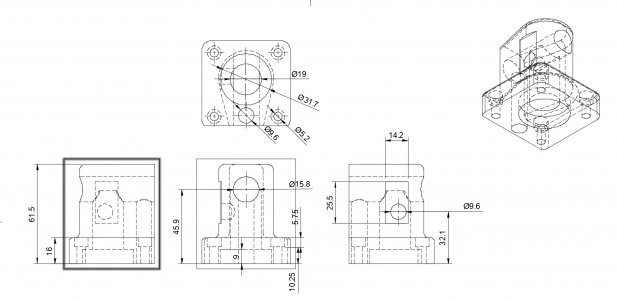

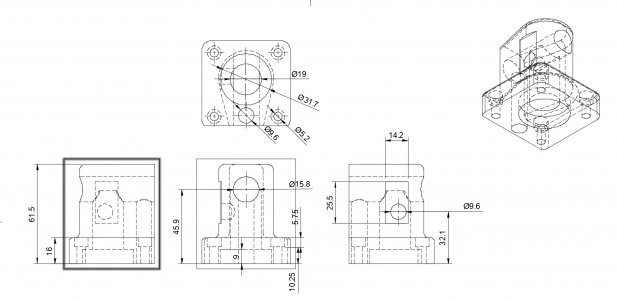

I also received the automatic advance lever block that I designed and had made by CNC. Small lick of paint. I still have to make the spring and put it back on the saddle.