H

Hukshawn

Forum Guest

Register Today

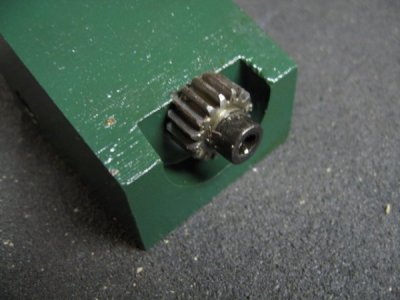

i was looking at my thread dial gear. it almost looks like someone made it. you can see scraping marks on the collar above the gear. why someone did this is anyones guess.

i started to figure out what i needed to make a new one.

i decided on 16t as i dont believe a 32t gear will fit within the dial housing.

the gear that is on there is 14t with a diameter of .600". i find this gear quite small and it jumps a bit when the keyway passes by.

so, if i take tubalcains math, i get a pitch of 26. (no idea if acme thread pitches are different... someone can correct me)

doing more math i determined i need a gear of 1.625" with a pitch of 26 with 16 teeth.

im sure i can find a website or an app that will help design a pie chart layout so i can just make this gear manually on the lathe, really. i was looking at a dividing head, and im still considering it, but, seems a bit much. but who knows when the next time ill actually need/want one and one will be available at a good price.

i started to figure out what i needed to make a new one.

i decided on 16t as i dont believe a 32t gear will fit within the dial housing.

the gear that is on there is 14t with a diameter of .600". i find this gear quite small and it jumps a bit when the keyway passes by.

so, if i take tubalcains math, i get a pitch of 26. (no idea if acme thread pitches are different... someone can correct me)

doing more math i determined i need a gear of 1.625" with a pitch of 26 with 16 teeth.

im sure i can find a website or an app that will help design a pie chart layout so i can just make this gear manually on the lathe, really. i was looking at a dividing head, and im still considering it, but, seems a bit much. but who knows when the next time ill actually need/want one and one will be available at a good price.