- Joined

- Feb 24, 2019

- Messages

- 956

Let's see if I get this right

I first cut the mounting plate to the quill. On the quill there's a plastic cap that can be removed with absolutely no ill effects. It appears to be decorative. This exposes about 1/4" of the quill to attach the plate to.

The four countersunk holes were to mount the piece to a faceplate to turn the hole in the center.

I left metal on the front of the plate to eventually add a positive stop for repetitive drilling without looking at the DRO all the time.

The ear on the left is milled slightly to allow the DRO mount plate to sit flush when the quill is all the way up. You can sort of see the milled area on the last pic.

The pick up unit is inside the hollow part of the mill head. I trimmed it to just barely not touch the top of the mill head.

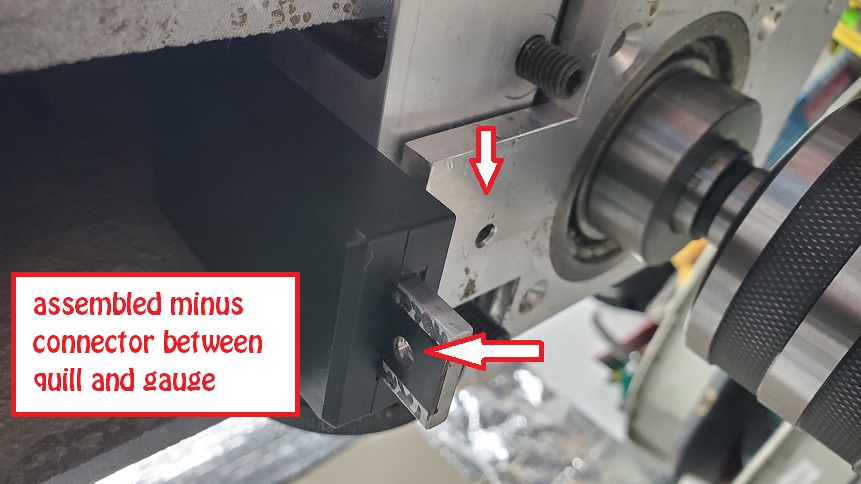

The slide will be connected to the quill plate with an aluminum block. I don't have it handy but you can get the idea.

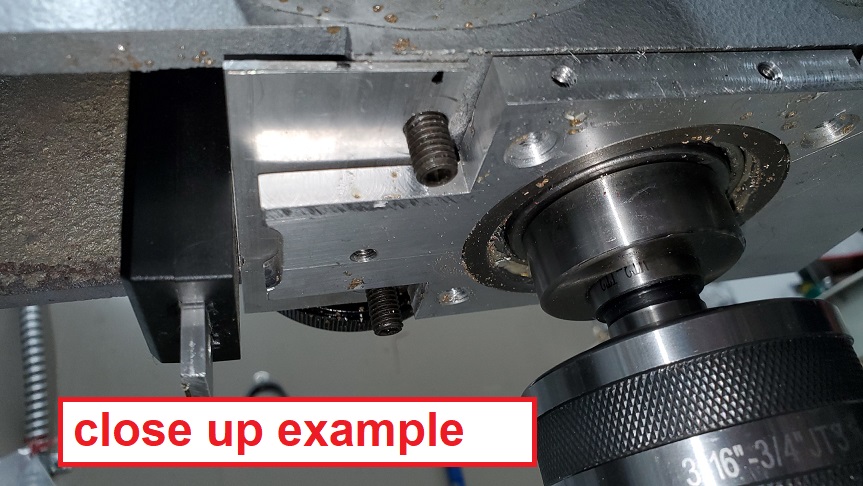

Here's a close up of it in position. The two studs on holding the DRO mount plate are actually holes that are already in place. I just put a couple long set screws there and hold it in place with nuts. I think they are M8 but don't hole me to that.

Hopefully this gives a good example of how it's set up.

I first cut the mounting plate to the quill. On the quill there's a plastic cap that can be removed with absolutely no ill effects. It appears to be decorative. This exposes about 1/4" of the quill to attach the plate to.

The four countersunk holes were to mount the piece to a faceplate to turn the hole in the center.

I left metal on the front of the plate to eventually add a positive stop for repetitive drilling without looking at the DRO all the time.

The ear on the left is milled slightly to allow the DRO mount plate to sit flush when the quill is all the way up. You can sort of see the milled area on the last pic.

The pick up unit is inside the hollow part of the mill head. I trimmed it to just barely not touch the top of the mill head.

The slide will be connected to the quill plate with an aluminum block. I don't have it handy but you can get the idea.

Here's a close up of it in position. The two studs on holding the DRO mount plate are actually holes that are already in place. I just put a couple long set screws there and hold it in place with nuts. I think they are M8 but don't hole me to that.

Hopefully this gives a good example of how it's set up.