- Joined

- Dec 3, 2013

- Messages

- 1,844

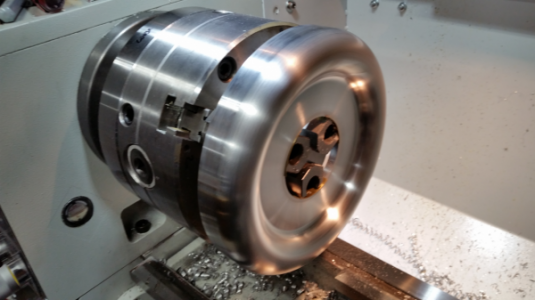

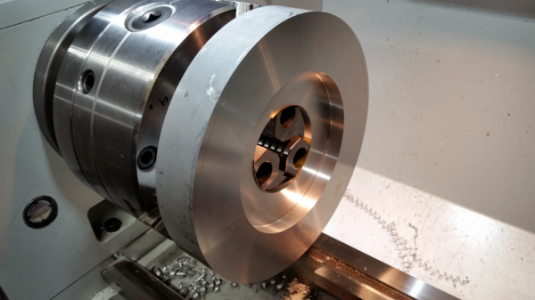

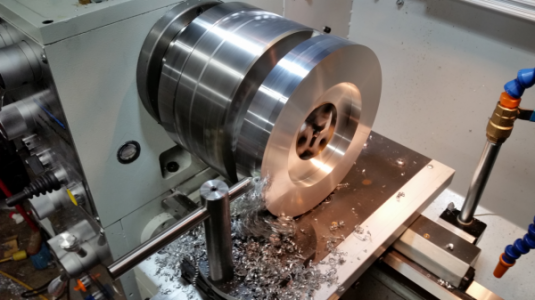

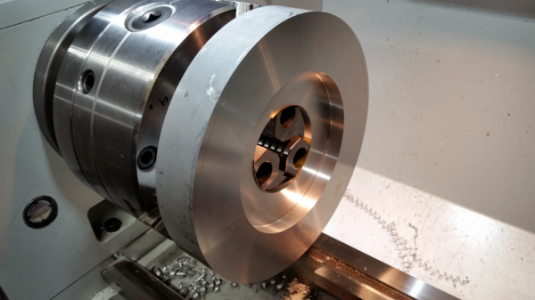

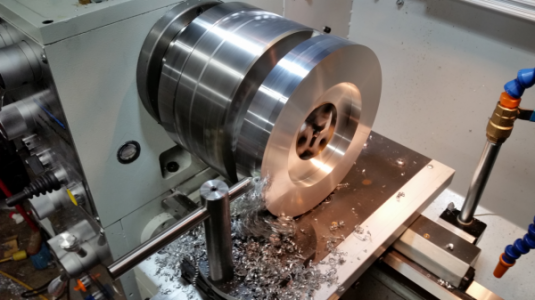

It turned out I did not need to make a fixture to hold the part for the radius turning. I was able to hold it in the 3-jaw with plenty of clearance. I locked down the radius turning tool and used it to cleanup the outside diameter. Worked great with no chatter.

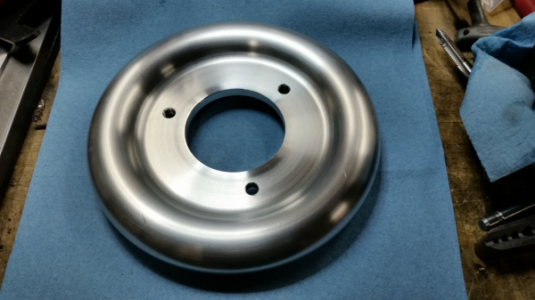

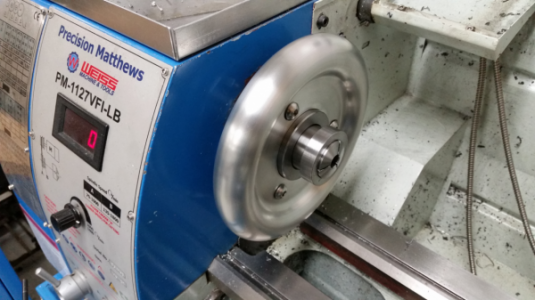

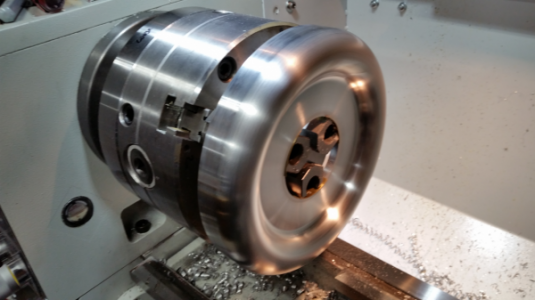

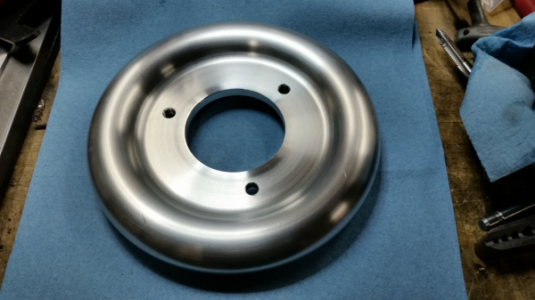

Once I figured out the correct speed & feed, turning the radius was a breeze with tool. Cleanup was done with some 320 wet/dry and then a scotch bright pad.

Once I figured out the correct speed & feed, turning the radius was a breeze with tool. Cleanup was done with some 320 wet/dry and then a scotch bright pad.