The radius on the tangential cutter?

Well as mentioned before, I have a version of Niels (FarFar) tangential tool cutter. I have been using since last yr. Also I have mentioned that I do most of my sharpening with a belt sander. The nose radius is somthing I put on my HSS tooling as a habit. Again, this is done on the belt sander.

I just use a 120 grit , well used belt, and the front nose edge that you would want the radius, just hold the HSS bit in your fingers, and rock the bit while running it on the belt. As usual, keep the cutting end to the trailing end of the belt. This will put a radius on the complete length of the tool bit in like 5-seconds. Your tooling will automaticly have a nose radius, and not a sharp pointy end. this gives a great finish.

Try it, you might like it.

Hello Paul

Can we have a picture of the way You round the nose?

There is a picture of how I try and if You advice us to do the same on a beltsander I will need clean clothes afterwards.

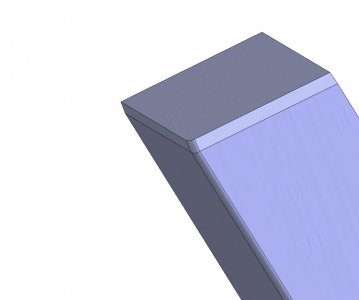

Now we are at it I will show facetting of a piece of tantung that is becoming my favourite tool material in a 12 degre tangential tool.

In a 12 degree tangtool the clearance for both edges is 8.5 degrre.Exesive but not much;anythingbetween 3 and seven deggre is better and very easy to make.

Last edited: