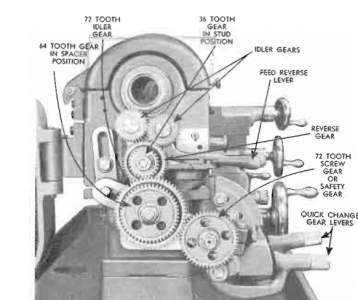

While I have family members who are machinists, and have operated lathes for basic functions, I am a "newbee" to owning/working on a lathe,...I have recently acquired a Logan 920....when I purchased it, it had a gear (labeled the stud gear in the Logan parts manual) on the reverse assembly that someone had tried to 3-d print, and while the gear appears to be well made, it doesn't engage the other idler gears as it should, so the forward/reverse function of the lead screw doesn't work. I have tried to isolate what exact gear it is and how many teeth it should have off of the illustration in the Logan parts lists, but can't seem to do so.....so I am asking for help.

........I can measure the thickness needed, the bore size needed, etc,....but is there a way for me to figure out the total teeth this gear should have when I don't have the original one? (the nylon one that doesn't work/doesn't engage,...has 24 teeth)

Thank you for any and all advice

........I can measure the thickness needed, the bore size needed, etc,....but is there a way for me to figure out the total teeth this gear should have when I don't have the original one? (the nylon one that doesn't work/doesn't engage,...has 24 teeth)

Thank you for any and all advice