-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I think this is my next project car

- Thread starter alloy

- Start date

- Joined

- Nov 28, 2016

- Messages

- 2,406

@alloy,

I'm concerned that because of the very shallow current drive shaft angle, when you pitch the pinion shaft up, you may find that the pinion shaft is higher than the trans yoke. I'm almost certain that it will be.

What would prevent you from raising the back of the transmission? Could you raise the trans tail shaft to get zero degrees incline on the trans?

That way you will only have to put a 2.2° shim on the rear end and you will get a closer to 3° drive shaft angle

I also feel that the pinion may wind up a little higher than the tailshaft... but I can't think of a reason why that would be an issue as long as the u-joint angles are within reason...

Just curious... how did you compute the 3 degrees for the driveshaft? I've been trying to figure that out, but I keep thinking that I would have to know the length of the driveshaft to determine that...

-Bear

D

Deleted member 69715

Forum Guest

Register Today

Spitballing here...

If the car on blocks is sitting on flat paved surface, try measuring from pavement to the visual center of both yokes. Just as a reference. Check with the klien gauge to see if that pavement is throwing your measurement wonky.

For measuring with the klien gauge at the rear, could a flat piece of plate be drilled to bolt to the u-joint carrier at the rear? Just to give a more consistent place to stick the klien gauge?

I've only had one cup of coffee, so like I said just spitballing.

If the car on blocks is sitting on flat paved surface, try measuring from pavement to the visual center of both yokes. Just as a reference. Check with the klien gauge to see if that pavement is throwing your measurement wonky.

For measuring with the klien gauge at the rear, could a flat piece of plate be drilled to bolt to the u-joint carrier at the rear? Just to give a more consistent place to stick the klien gauge?

I've only had one cup of coffee, so like I said just spitballing.

- Joined

- Nov 24, 2014

- Messages

- 3,199

I also feel that the pinion may wind up a little higher than the tailshaft... but I can't think of a reason why that would be an issue as long as the u-joint angles are within reason...

Just curious... how did you compute the 3 degrees for the driveshaft? I've been trying to figure that out, but I keep thinking that I would have to know the length of the driveshaft to determine that...

-Bear

I estimated the following:

Front engine mount to trans yoke = 48"

From 3.3° incline, raising the trans rear 2.76" at the yoke will result in a 0° engine/trans incline.

Distance from rear axel C/L to pinion yoke = 12"

From a 2.2° incline, pivoting the pinion axis up .46" at the yoke will result in a 0° pinion axis incline, so engine/trans axis is parallel to pinion axis.

'55 Bel Air has a 115" wheel base. Rough estimate: 115-36=67-12= 55" long drive shaft (yoke to yoke)

At a 1.2° incline and a 55" drive shaft, the trans yoke is currently 1.15" higher than the pinion yoke.

Per my estimates, If he raises the trans yoke 2.76" and the pinion yoke .46" (2.76-.46=2.30"+1.15=3.45"), with a 55 " long drive shaft, it results in a 3.6° drive shaft angle.

@alloy

How long is the drive shaft, yoke C/L to yoke C/L? Tape measure is fine.

What is the dimension from the pinion yoke C/L to the rear axle axis? Tape measure is fine.

Last edited:

- Joined

- Nov 24, 2014

- Messages

- 3,199

I mean it this time!See you boys tomorrow!

- Joined

- Nov 28, 2016

- Messages

- 2,406

I haven't done the math... but just 'guesstimating' from the above numbers, leaving the transmission where it is and raising the pinion 5 degrees will give between 3 and 3.5 degrees operating angle on the u-joints... the driveshaft will be very close to level... and the pinion should still be slightly lower than the tailshaft...

Am I guesstimating that correctly? Or is that some 5am thinking? Lol!

-Bear

Am I guesstimating that correctly? Or is that some 5am thinking? Lol!

-Bear

- Joined

- Jan 28, 2011

- Messages

- 3,497

- Joined

- Jan 28, 2011

- Messages

- 3,497

Found this

www.motortrend.com

www.motortrend.com

https://www.trifive.com/threads/pinion-angle-confusion.225872/

How To Set Pinion Angle

Pinion angle simply refers to the angle of the differentials pinion in relation to the driveshaft. But ask 10 guys about optimal pinion angle and a lively debate will ensue. To

https://www.trifive.com/threads/pinion-angle-confusion.225872/

- Joined

- Jul 5, 2014

- Messages

- 2,782

Boy, a lot of info to digest.

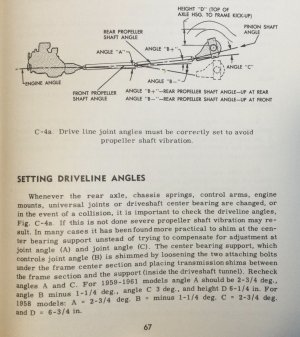

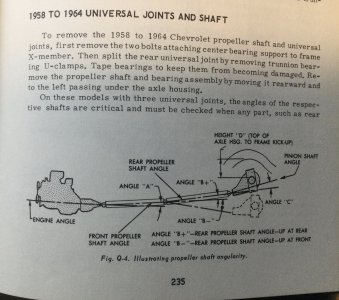

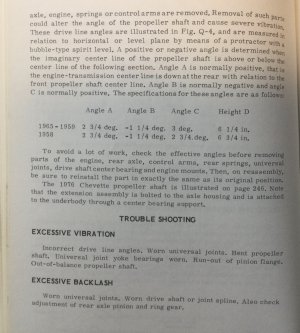

And I just realized I set the engine/trans wrong. The tri-5 thread has this. (see pic) In my frustration I just said the heck with it and stuck the angle finder to the trans pan and as it turns out that's not going to cut it. In thinking about it after seeing the trr-5 post the trans pan is probably tilted 3.5 degrees to keep the fluid level the same front to back whith the engine and trans at an angle. If it was not angled then the fluid level would be off and might cause problems with the transmission. I think I'll probably just pop the carb off and check the angle on the manifold flange. Those dang engineers were pretty sharp on this one. They outfoxed me for sure on this. I'm really thankful you posted the link. Kept me from making a big mistake.

I'll do some more adjusting and post what the new numbers are. I never figured this would turn out to be such a big deal. But it's critical to get it right.

I have parts to work on today so it may be awhile before I get to this. For some reason my left arm is really hurting, very hard to use it today. I didn't sleep last night because of it. It's hell getting old it seems, this hurts, that hurts. Did something to it yesterday doing all this, even had a dream about it. Not a good dream. Wife is grumpy this morning because I kept her up most of the night.

Stay tuned............same bat-channel, same bat-time

And I just realized I set the engine/trans wrong. The tri-5 thread has this. (see pic) In my frustration I just said the heck with it and stuck the angle finder to the trans pan and as it turns out that's not going to cut it. In thinking about it after seeing the trr-5 post the trans pan is probably tilted 3.5 degrees to keep the fluid level the same front to back whith the engine and trans at an angle. If it was not angled then the fluid level would be off and might cause problems with the transmission. I think I'll probably just pop the carb off and check the angle on the manifold flange. Those dang engineers were pretty sharp on this one. They outfoxed me for sure on this. I'm really thankful you posted the link. Kept me from making a big mistake.

I'll do some more adjusting and post what the new numbers are. I never figured this would turn out to be such a big deal. But it's critical to get it right.

I have parts to work on today so it may be awhile before I get to this. For some reason my left arm is really hurting, very hard to use it today. I didn't sleep last night because of it. It's hell getting old it seems, this hurts, that hurts. Did something to it yesterday doing all this, even had a dream about it. Not a good dream. Wife is grumpy this morning because I kept her up most of the night.

Stay tuned............same bat-channel, same bat-time

Last edited: