- Joined

- May 13, 2019

- Messages

- 1,016

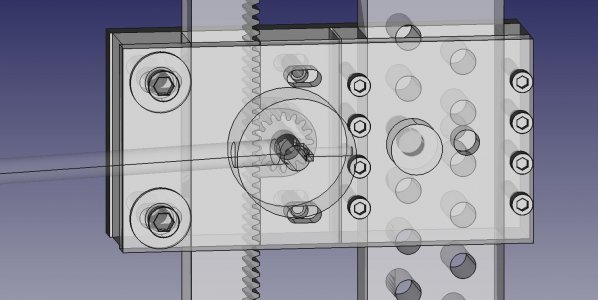

So, the set of gear cutters I ordered are M1.25, PA20 Bore 22 mm. I'm looking for a R8 arbor for this. I've contacted a few eBay sellers asking about their products and can't get a decent answer. Search on eBay: "USA 22mm R8 Shank Milling Arbor Gear Mill Cutter Holder Toolholding 7/16-20" for what I'm thinking.

I'm assuming this will work?

I asked if the arbor was keyed and didn't get a response. Can anyone help here?

I'm assuming this will work?

I asked if the arbor was keyed and didn't get a response. Can anyone help here?

Last edited: