Hi; cutting your own gear. Is a good project even if buying them is cheaper. Look around and see what is available in your area sometime at scrapyard there some old equipment that there would be a rack you can use. The rack are not expensive to buy . I would use around a 16 DP size it seem this would work good for your project. As soon you have the rack then you can plan on building the gear.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I want to cut my first gear

- Thread starter devils4ever

- Start date

-

- Tags

- freecad gear cutting

- Joined

- May 13, 2019

- Messages

- 1,016

I have some of the tooling now. I have the R8 - 22 mm arbor and the gear cutters from China have arrived. They look decent and the set is complete with no missing or duplicate cutters. I'll be using them shortly and report how they cut. I also have the 20 degree end mills to cut the rack.

I have materials on order and I ordered the Shars No 00 keyway cutting broaching set. I'm looking forward to getting started.

I have materials on order and I ordered the Shars No 00 keyway cutting broaching set. I'm looking forward to getting started.

- Joined

- May 13, 2019

- Messages

- 1,016

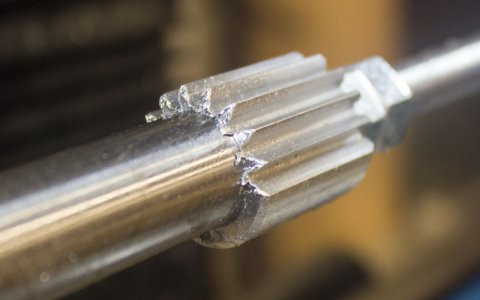

Can someone check my numbers?!? I'm doing some test cuts and the teeth look way too pointy/sharp at the top.

Given:

N = 16

M = 1.25

PA = 20

Computed:

OD = (N+2) * M = (16+2) * 1.25 = 22.5mm = 0.886"

Whole depth = 2.25 * M = 2.8125mm = 0.111"

Given:

N = 16

M = 1.25

PA = 20

Computed:

OD = (N+2) * M = (16+2) * 1.25 = 22.5mm = 0.886"

Whole depth = 2.25 * M = 2.8125mm = 0.111"

- Joined

- May 13, 2019

- Messages

- 1,016

- Joined

- Dec 18, 2019

- Messages

- 6,513

Your numbers seem to be to the standard formulas, but I agree, the teeth look sharp. Then again, you only have 16T. The smallest gear I could find was a 20T and 21T M1 gear and they definitely have flats on the teeth tops. I'm guessing you are going too far in. Another thing to check is the tooth height. Is it 0.111" measured? It you went in too deep the sharp tips would form.Can someone check my numbers?!? I'm doing some test cuts and the teeth look way too pointy/sharp at the top.

Given:

N = 16

M = 1.25

PA = 20

Computed:

OD = (N+2) * M = (16+2) * 1.25 = 22.5mm = 0.886"

Whole depth = 2.25 * M = 2.8125mm = 0.111"

Ruling out any operator error for the sake of argument, are you sure these are Module 1.25 cutters? Is there something you can check on the cutter profile to be sure? Just because they are marked M1.25 doesn't mean they are... Or some craziness with the 1-8 cutters being mis-marked or backwards? US customary numbers are backwards compared to the Chinese ones... My cutters do have a number (of teeth) range marked on the cutters, yours do too?

- Joined

- Dec 18, 2019

- Messages

- 6,513

I took my numbers from: http://www.metrication.com/engineering/gears.html FWIW.

- Joined

- May 13, 2019

- Messages

- 1,016

Yeah, I'm not sure how to measure tooth height. Suggestions?

The cutters are marked M1.25, but who knows! The cutter I'm using is marked #2 14-16. The only other gears I have are from my mini-lathe which are M1.0, I believe. The depth on these is really small compared to what I cut.

I touched off on the side of the gear blank with the cutter and moved the Y-axis in 0.111".

The cutters are marked M1.25, but who knows! The cutter I'm using is marked #2 14-16. The only other gears I have are from my mini-lathe which are M1.0, I believe. The depth on these is really small compared to what I cut.

I touched off on the side of the gear blank with the cutter and moved the Y-axis in 0.111".

- Joined

- Dec 18, 2019

- Messages

- 6,513

Honestly don't know. It's like one needs a very small pin or very thin depth gauge. There's probably some smart person that has figured out how to use a round pin of the right size that just lies on the teeth and know the important details from that... Kind of like measuring dovetails. Maybe you could doodle in CAD with something like that?Yeah, I'm not sure how to measure tooth height. Suggestions?

When things get back to normal here, I can think about it some more. Have to take my kids and grandson to the airport soon, so it's going to get crazy here in a few minutes!

- Joined

- May 13, 2019

- Messages

- 1,016

I found this website to use pins for measurement.

Using 0.125" pins (3.175mm), the distance over the pins is 1.023". I measure about 1.001" - 1.002". Somethings off!!!

Using 0.125" pins (3.175mm), the distance over the pins is 1.023". I measure about 1.001" - 1.002". Somethings off!!!