I made some progress on the solid QCTP mount.

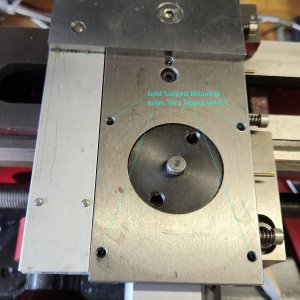

I found that I really need to include a 3/32" shim riser for some cutting tools, mostly small diameter boring bars. The main 1.5" thick riser block is not quite enough to get a boring bar cutting point just above the spindle axis, or even dead on it. For most turning operations though, the riser block is tall enough.

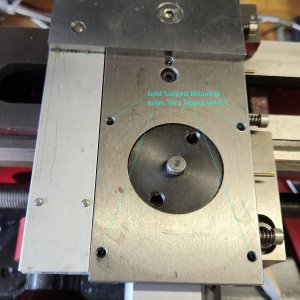

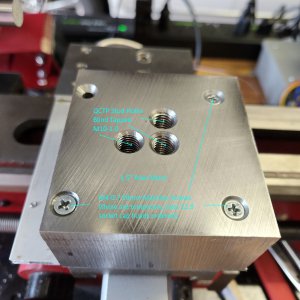

Here's the cross-slide showing the four M4-0.7 thru-tapped holes in the dovetails:

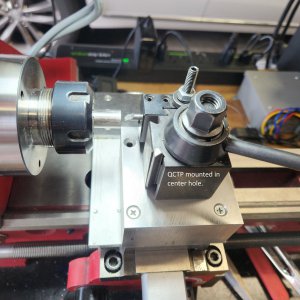

Here's the block and shim temporarily installed, the block is mounted above the shim:

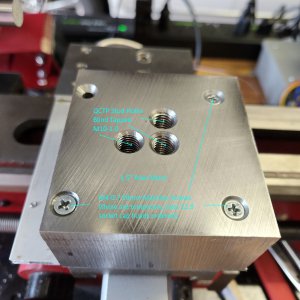

I drilled and blind tapped 3 M10-1.0 holes for the QCTP stud, the one furthest in from the cutting tool edges offers the most rigid position for the tool post but that may cause the block to contact the chuck before the cutter is where it needs to be on the part. The two other holes give up some rigidity but ensure that the cutter leads the mounting block into the work.

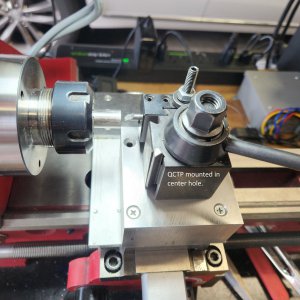

Here's the final assembly, including the QCTP with a boring bar:

I'm in a quandary as far as achieving a super flat and smooth finish on the shim riser and mounting block; I spent a couple hours going at it with sandpaper on a float glass plate, just not seeing any serious progress. A friend works at a local automotive machine shop, he might be able to run the riser block through a head grinding machine for me, but the shim riser may be too short for the machine.

I'd also like to add a jam of some sort to prevent the QCTP from swiveling, even though I've never see it actually do that.

Once I get the new screws it'll be time to make some chips

.