- Joined

- Jan 23, 2015

- Messages

- 60

Hi All,

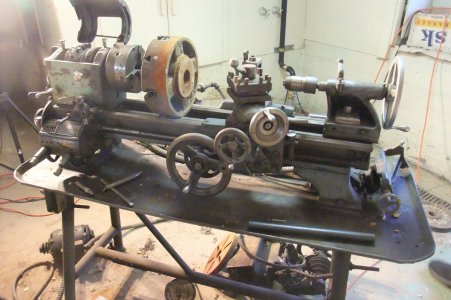

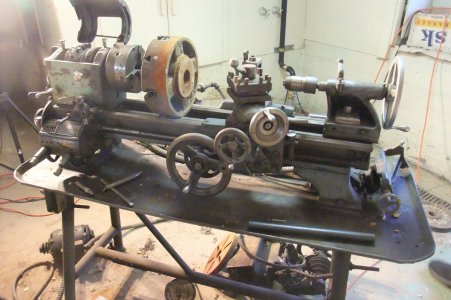

Just purchased this 10 inch Montgomery Ward/Logan 701A. At least that's what it says on the attached plate.

Serial number is a bit confusing to me as there are three separate numbers on the right hand end of the bed.

One is 69. There is an inch or so of space and the 1065P. Below that the numers 9898. I'm assuming the 1065P is the serial and that this is a 1947 or 48 year lathe. There is the letter W stamped in between the ways on the rear right hand of the bed.

Cast into the rear side of the bed is a raised diamond shape with letters that look like BHF (very hard to read) and above that a cast in date 1-19-48 (could possibly be 1-19-46 as the last numeral is also very hard to read.

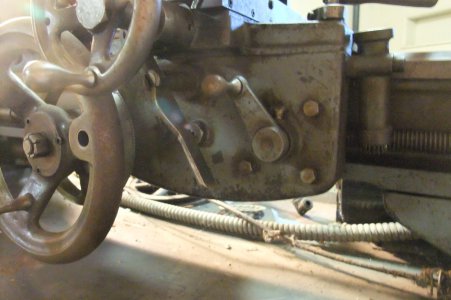

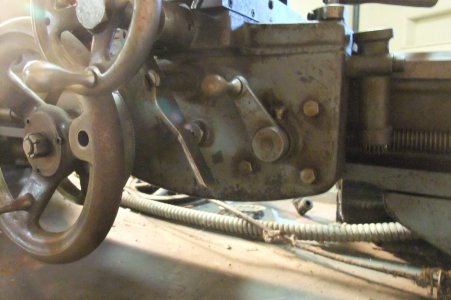

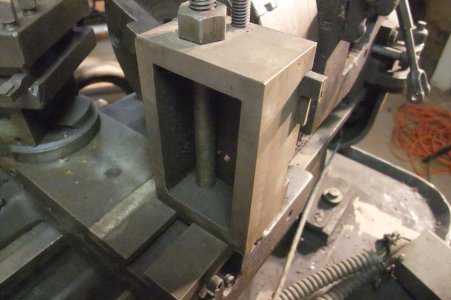

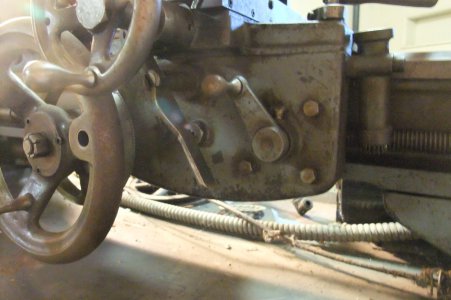

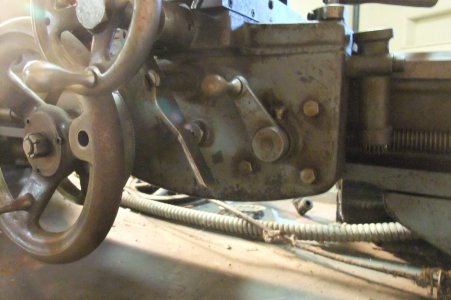

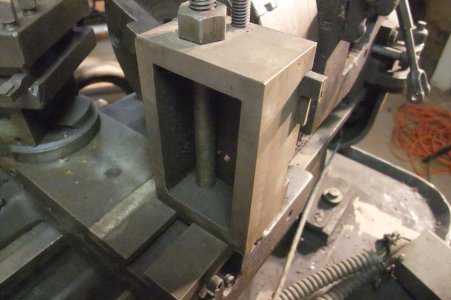

The lathe has some interesting features: New-All quick change threading attachment, a turret carriage stop with four positions, some kind of tool holder on the back side of the cross slide. It has what looks to be a cut off tool in it. It has a 3-jaw chuck mounted. A larger 4-jaw chuck that might be too large for this lathe and a face plate which also looks to be too large were in the box of 'extras'. Tool holder is a four tool of the type often seen and the original lantern style tool holder is in the box. A dozen or so extra gears that probably were original and before the New-All quick change threading box. A set of extra jaws for the 3-jaw chuck. A milling attachment that looks like a Craftsman/Atlas was also in the parts box.

The ways look good and the carriage, when tightened some cranks with fairly even pressure along the length of the ways. Hand cross feed works OK as does the compound feed.

The motor and motor carrier/countershaft(?) and pulley assembly was disassembled when I looked at the lathe. There is an older 1/3 hp 220V motor that looks as oily as the rest of the lathe so may have been on it at some point. And there is a newer 1/2 hp frigidare 1750 rpm single phase motor with the parts.

A curious hole and tool on the front side of the headstock. The tool and hole are located so when the tool is pushed in it locks the large gear in the headstock. I am presuming this is to enable removal of chuck???.

I haven't examined everything closely but have not located the hole or the insert to engage the back gear. Maybe I haven't looked close enough or the lever at the left side of the headstock does that function? I'm an obvious newbie to the machine tool world so a whole lot more I don't know than do know. For example while I've figured out some of the controls on the carriage some remain a bit of a mystery particularly since its not powered at this point.

I've disassembled everything I can and brought home parts to clean up and check out. The table it sits on and the bed and headstock with carriage are still at the previous owner's place. I will move those this Sat. when I can recruit some young and stronger-than-me help. Table appears to be a very well done home-made unit with an oil/coolant reservoir built in and a couple of belt driven oil pumps and some piping were included in the parts boxes.

I'm going to take my time cleaning up and assembling to make sure what I got is worth continuing to fix up and maybe purchase some better things for, but don't want to get the cart ahead of the horse here.

Any help from those of you with similar lathes as to whether I'm accurately describing what I purchased would be greatly appreciated. I'd like to know if this is a regular lathe with some options or a thrown-together hodge-podge of lathe parts. I really do want it to be a good old lathe than can be brought back to life and make chips but if that can't be done at some reasonable cost the obvious exit strategy is to part it out.

I am currently enrolled in a night class on machine shop at a local community college and am on my 3rd quarter of the class so what I've been learning about lathe and other machine operations will come in very handy.

I don't think the financial risk is much as I'm in this $300. at this point. No doubt if it proves to be a decent running lathe the costs for tooling and an endless array of other tempting things will skyrocket the costs.

Jerry

ps. on the copy of this post I viewed the picture of the whole lathe appears out of place. Don't know how that happened. Maybe one of the moderators can fix?

Just purchased this 10 inch Montgomery Ward/Logan 701A. At least that's what it says on the attached plate.

Serial number is a bit confusing to me as there are three separate numbers on the right hand end of the bed.

One is 69. There is an inch or so of space and the 1065P. Below that the numers 9898. I'm assuming the 1065P is the serial and that this is a 1947 or 48 year lathe. There is the letter W stamped in between the ways on the rear right hand of the bed.

Cast into the rear side of the bed is a raised diamond shape with letters that look like BHF (very hard to read) and above that a cast in date 1-19-48 (could possibly be 1-19-46 as the last numeral is also very hard to read.

The lathe has some interesting features: New-All quick change threading attachment, a turret carriage stop with four positions, some kind of tool holder on the back side of the cross slide. It has what looks to be a cut off tool in it. It has a 3-jaw chuck mounted. A larger 4-jaw chuck that might be too large for this lathe and a face plate which also looks to be too large were in the box of 'extras'. Tool holder is a four tool of the type often seen and the original lantern style tool holder is in the box. A dozen or so extra gears that probably were original and before the New-All quick change threading box. A set of extra jaws for the 3-jaw chuck. A milling attachment that looks like a Craftsman/Atlas was also in the parts box.

The ways look good and the carriage, when tightened some cranks with fairly even pressure along the length of the ways. Hand cross feed works OK as does the compound feed.

The motor and motor carrier/countershaft(?) and pulley assembly was disassembled when I looked at the lathe. There is an older 1/3 hp 220V motor that looks as oily as the rest of the lathe so may have been on it at some point. And there is a newer 1/2 hp frigidare 1750 rpm single phase motor with the parts.

A curious hole and tool on the front side of the headstock. The tool and hole are located so when the tool is pushed in it locks the large gear in the headstock. I am presuming this is to enable removal of chuck???.

I haven't examined everything closely but have not located the hole or the insert to engage the back gear. Maybe I haven't looked close enough or the lever at the left side of the headstock does that function? I'm an obvious newbie to the machine tool world so a whole lot more I don't know than do know. For example while I've figured out some of the controls on the carriage some remain a bit of a mystery particularly since its not powered at this point.

I've disassembled everything I can and brought home parts to clean up and check out. The table it sits on and the bed and headstock with carriage are still at the previous owner's place. I will move those this Sat. when I can recruit some young and stronger-than-me help. Table appears to be a very well done home-made unit with an oil/coolant reservoir built in and a couple of belt driven oil pumps and some piping were included in the parts boxes.

I'm going to take my time cleaning up and assembling to make sure what I got is worth continuing to fix up and maybe purchase some better things for, but don't want to get the cart ahead of the horse here.

Any help from those of you with similar lathes as to whether I'm accurately describing what I purchased would be greatly appreciated. I'd like to know if this is a regular lathe with some options or a thrown-together hodge-podge of lathe parts. I really do want it to be a good old lathe than can be brought back to life and make chips but if that can't be done at some reasonable cost the obvious exit strategy is to part it out.

I am currently enrolled in a night class on machine shop at a local community college and am on my 3rd quarter of the class so what I've been learning about lathe and other machine operations will come in very handy.

I don't think the financial risk is much as I'm in this $300. at this point. No doubt if it proves to be a decent running lathe the costs for tooling and an endless array of other tempting things will skyrocket the costs.

Jerry

ps. on the copy of this post I viewed the picture of the whole lathe appears out of place. Don't know how that happened. Maybe one of the moderators can fix?

Last edited by a moderator: