I've been casting bullets from wheel weights for 30- something years, mostly for .44 Magnum, .30 carbine, and 30.06... I've also probably made over a ton of lead shot for shotgun reloading.

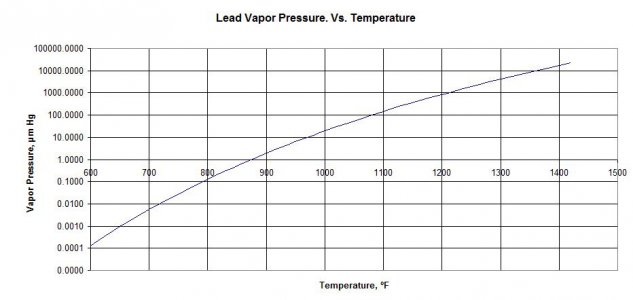

No offense intended, but your setup makes me nervous... there is no way to control how hot the lead becomes. I've been taught that as long as the lead is silver, it is safe. If it starts taking a gold tint, it's time to lower the heat input. If it begins looking purple, it is about to start 'outgassing'... and you need to be wearing a respirator...

-Bear

None taken, and many thanks for the response.

I know that there is accumulated experience here that includes years of discovering stuff that is not such a good idea!

One of the reasons I put it in the woodburner is because I wanted it to be where it could not hurt me. I didn't fancy pouring anything, and just standing a can of lead in there seemed like a simple scheme that avoids much of the work and skills needed to do it any other way.

There is a temperature gauge indicator mounted on the cast iron body above the doors, with "most efficient" range marked 100C to 400C. Of course, there are wood coals in there glowing red, which is way more than 400C. The design is modern, arranged with two air inlet routes, one of which takes (very) hot air through the fire, up, and guided back to the front at the top, to descend across the quartz windows. That air is hot enough to turn any carbon smuts and deposits into CO2, and keeps the windows clear. All that is left is a very fine white ash which wipes off with a wet cloth.

I am OK with metal being outgassed of trapped air, which is a different thing to the toxic vaporizing metal off the top, which happens all the time once it is molten. The air that enters the woodburner for combustion can only end up going up the flue, and would take lead vapors with it, to become white lead oxide ash. As a sort of "smelter's fume cupboard", I am thinking it might be a whole lot safer than melting a batch on a welding table. While the lead was melting, I was not even there!

Estimating from the colour of the red, the temperature of the thin metal above the molten lead was about 700C (about 1292°F). The lead below was glowing very faintly red, I estimate about 580 to 600C, which is much hotter than needed. The "can" was, of course, completely unsuitable other than to simply let it cool in there. Once the lead was liquid, the can could not be gripped by anything without being a softer-than-usual, squishy, thin-walled can again, so there it stayed overnight.