- Joined

- Jan 11, 2013

- Messages

- 1,821

Hey Everyone!

First off- does anyone have one of these? I will have some questions for you!

A few months ago I was asking advice (read as "whining and alagoning") about two drill presses not doing what I needed, and wanting to find one to solve ALL my drilling problems.

For future drill press info searchers, here is that whining thread:

http://www.hobby-machinist.com/show...-Quandary-(self-created-)?p=126915#post126915

My concerns were:

-Needed MT2 Spindle - since I already have loads of MT2 tooling.

-Floor Model

-Geared table elevation- I have a large 6x20-ish X-Y table for positioning work.

-SLOW spindle option- I didn't care of it was VFD, or pulleys.

Well, I found one on Craigslist! With terrible pictures! Laughably bad pictures! Look at these:

They were even posted crooked like this! Hah hah.

It was listed as a Walker Turner. I think scale is always hard to determine when it comes to post-mounted drill presses, but even these bad pics gave a few clues. I could tell by the table and the foot that it COULD be a 17 or 20 inch machine, so I called the guy right away!

When I showed up, I almost laughed out loud, because it is humongous!

This is definitely the largest of this post-style drill presses I have seen in person- this thing is a BEAST!! According to the catalog, delivery weight is 500lbs! I have seen bigger drilling machines, but they are all cast iron bodied, gear-head or camelback machines.

As it turns out, this is a Walker Turner D1100 20 Inch Drill Press.

It is funny to see myself next to it- it's like i'm in kindergarten hah hah- it's over 6 feet tall! Here it is just in my garage:

The previous owner purchased it at a school auction, from Somerville High School in NJ, and stored it for 10 years. Didn't look bad at all though! The only issues being a bad belt, a gummed up table-gear mechanism (pics below WOW), a light arc of shame (not bad after leaving a school shop), and a frozen table-to-column which I knew was not a real problem.

Plenty of room to work, and T-slots! I always wondered what professional shops do with production tables without T-slots?

The seller helped load the truck, and when I got it home, I performed the tilt and lift out if the back of the pickup to stand it up at the door of my garage shop:

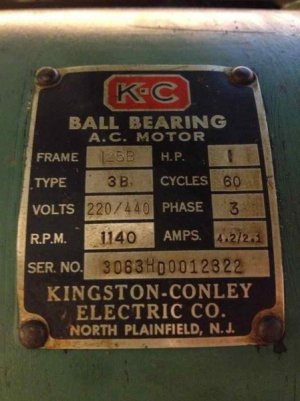

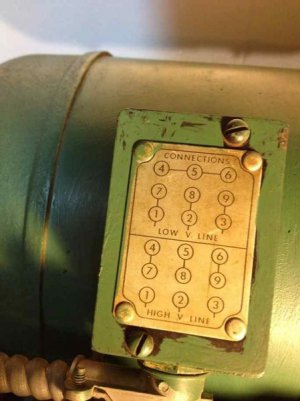

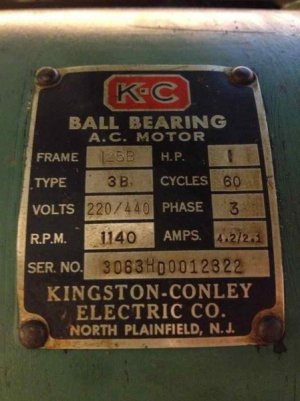

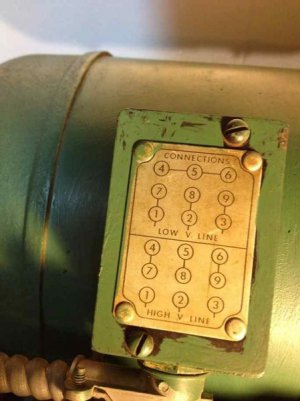

It has an 1140 RPM 3 Phase motor, which looks original.

Question 1---- Anyone ever put a VFD on a lower RPM motor like this? The slow speed is 260 RPM with this motor, but I'm trying to get 100 or less for trepanning 6 inch aluminum. If I don't make another pulley to slow it down, I think that's pretty VFD-able.

After freeing the the table from the column with Liquid Torch, the elevating mechanism still felt pretty yucky and kept sticking. I locked the table, and removed the housing for the riser gear- and a liquid that beads on oil poured out!! I don't understand what it could be and have no rust inside:

(See suspicious puddle of liquid on foot)

I have cleaned up a lot of machines, but I have NEVER seen such yucky, gritty, gooey crap CraMMed inside something like this, but it took 45 minutes to clean it all out:

After Superlube Grease on the worm gear, reassembly, and using a car jack to get the table to a clean part of the column, it worked like a charm!

So the next jobs are:

-Wire it up and test the motor

-Raise the table elevating rack a few inches into a more useful range

-Either VFD or rig up a speed reduction pulley

-Add the X-Y table

-Move it 20 feet into place!

So here it sits:

Updates and questions to come!

Bernie

First off- does anyone have one of these? I will have some questions for you!

A few months ago I was asking advice (read as "whining and alagoning") about two drill presses not doing what I needed, and wanting to find one to solve ALL my drilling problems.

For future drill press info searchers, here is that whining thread:

http://www.hobby-machinist.com/show...-Quandary-(self-created-)?p=126915#post126915

My concerns were:

-Needed MT2 Spindle - since I already have loads of MT2 tooling.

-Floor Model

-Geared table elevation- I have a large 6x20-ish X-Y table for positioning work.

-SLOW spindle option- I didn't care of it was VFD, or pulleys.

Well, I found one on Craigslist! With terrible pictures! Laughably bad pictures! Look at these:

They were even posted crooked like this! Hah hah.

It was listed as a Walker Turner. I think scale is always hard to determine when it comes to post-mounted drill presses, but even these bad pics gave a few clues. I could tell by the table and the foot that it COULD be a 17 or 20 inch machine, so I called the guy right away!

When I showed up, I almost laughed out loud, because it is humongous!

This is definitely the largest of this post-style drill presses I have seen in person- this thing is a BEAST!! According to the catalog, delivery weight is 500lbs! I have seen bigger drilling machines, but they are all cast iron bodied, gear-head or camelback machines.

As it turns out, this is a Walker Turner D1100 20 Inch Drill Press.

It is funny to see myself next to it- it's like i'm in kindergarten hah hah- it's over 6 feet tall! Here it is just in my garage:

The previous owner purchased it at a school auction, from Somerville High School in NJ, and stored it for 10 years. Didn't look bad at all though! The only issues being a bad belt, a gummed up table-gear mechanism (pics below WOW), a light arc of shame (not bad after leaving a school shop), and a frozen table-to-column which I knew was not a real problem.

Plenty of room to work, and T-slots! I always wondered what professional shops do with production tables without T-slots?

The seller helped load the truck, and when I got it home, I performed the tilt and lift out if the back of the pickup to stand it up at the door of my garage shop:

It has an 1140 RPM 3 Phase motor, which looks original.

Question 1---- Anyone ever put a VFD on a lower RPM motor like this? The slow speed is 260 RPM with this motor, but I'm trying to get 100 or less for trepanning 6 inch aluminum. If I don't make another pulley to slow it down, I think that's pretty VFD-able.

After freeing the the table from the column with Liquid Torch, the elevating mechanism still felt pretty yucky and kept sticking. I locked the table, and removed the housing for the riser gear- and a liquid that beads on oil poured out!! I don't understand what it could be and have no rust inside:

(See suspicious puddle of liquid on foot)

I have cleaned up a lot of machines, but I have NEVER seen such yucky, gritty, gooey crap CraMMed inside something like this, but it took 45 minutes to clean it all out:

After Superlube Grease on the worm gear, reassembly, and using a car jack to get the table to a clean part of the column, it worked like a charm!

So the next jobs are:

-Wire it up and test the motor

-Raise the table elevating rack a few inches into a more useful range

-Either VFD or rig up a speed reduction pulley

-Add the X-Y table

-Move it 20 feet into place!

So here it sits:

Updates and questions to come!

Bernie