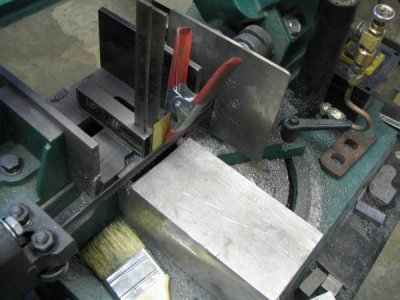

I just picked up a rong-fu RF-115 4x6 bandsaw today for $50. Guy was nice, I did a test cut and even though it did not cut quite straight, it cut through 2" solid round 6061. Brought it home and tried three times, and all three times the blade binded and stalled the motor.

I am brand new to horizontal band saws, and have no idea where to start to get it to work, and cut straight. Does anyone have a manual for this machine?

thank you to anyone who can help

I am brand new to horizontal band saws, and have no idea where to start to get it to work, and cut straight. Does anyone have a manual for this machine?

thank you to anyone who can help