- Joined

- Jun 24, 2013

- Messages

- 72

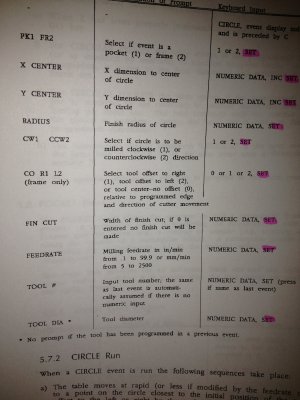

i just bought a mill with a prototrak plus , everything works great other the user (me) can't stop it from running 4" cirlce program i set in it . try to set bolt hole and it jumps to circle again . question about tool no# it asks for in the last 2 steps then dia of bit . don't know what tool no# means . wondering if its set from last owner and remembers his tools no#s any help would be great , don't want to cut 4" circles the rest of my life .