- Joined

- Jul 27, 2013

- Messages

- 295

Eureka!

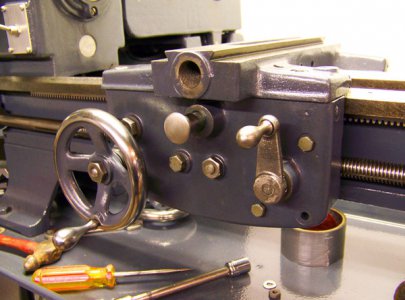

In a desperate attempt to stay ahead of TomKro in our rebuild slow race to nowhere in particular, I WORKED ON MY LATHE TODAY! This is yet another example where I've dragged my feet on some perception of evil and doom lurking in the project just ahead, only to find it was a no brainer and wasn't worth a scintilla of fret.

What had been holding me up was gear binding. My lathe has been crashed into oblivion numerous times in its life, to the point that the idler shift gear LA-191 was completely missing, rendering the cross feed drive inoperable. The bearing bracket LA-196 was broken and had been welded; a fairly common malady for these lathes. Both the remaining miter gears LA-188 and 189 that drive the idler show the scars of battle, having some fairly significant tooth deformation in spots. The very nice used idler gear I purchased did not mesh well with 188. A bit of sleuthing showed a couple of things. First, as Mister Ed posited, there is indeed a bend in the pin that the idler shift gear rides on, but I don't think it is enough to cause a problem. Second, 188 did have a couple of well dented teeth that caught every time. Imagine a crash violent enough to break brackets, bend gear teeth way out in the apron, and bend the idler shift pin?! A little profiling with a file and 188/191 run nice and smooth. Certainly nothing to stew over for 6 months! So... very quickly, we are here;

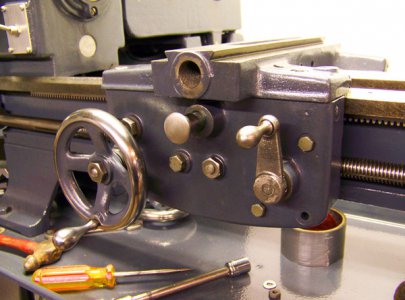

Lots of juggling trying to get all this stuff together, as anyone who has ever done it knows. The biggest problem with aprons is you can't see what the hell you are doing back there. The last thing I snugged down was the LA-196 bearing bracket, and the next problem became apparent; the lead screw won't turn.

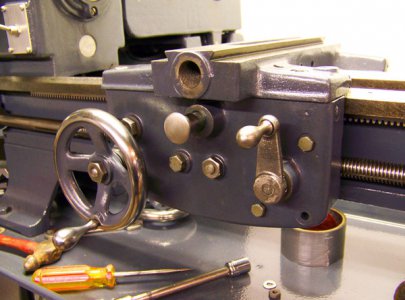

Loosen the bolt that holds the bracket to the apron and it turns fine. Tighten it again, and it binds. Pretty dang hard to see anything back there, but looking in all the way from past the change gear area shows the bearing bracket cocking upward when the bolt is snugged, jamming into the lead screw and bowing it upwards. I have no idea when the repair to LA-196 was done (although it appears to be done well), whether the lathe actually ever ran after that, or whether it has anything to do with this at all, but I now have to come up with a fix. :thinking:

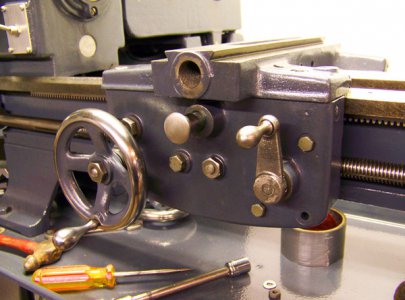

Right off the top of my head, I can think of two ways. The easiest thing to do would be to open up the hole in the apron to allow for some adjustment, but I'm not sure that is the best way. The other would be to tear it all back apart again and attempt to set up the bracket on the mill such that I could change the angle of the mounting surface a bit. The difficulty in actually doing that accurately (how to measure how much?) is nudging me toward the inelegant fix, even though I dislike the thought quite a bit.

One thing I will say is that it won't take me another 6 months to decide. Gotta stay ahead of Tom, after all.

One thing I will say is that it won't take me another 6 months to decide. Gotta stay ahead of Tom, after all.

In a desperate attempt to stay ahead of TomKro in our rebuild slow race to nowhere in particular, I WORKED ON MY LATHE TODAY! This is yet another example where I've dragged my feet on some perception of evil and doom lurking in the project just ahead, only to find it was a no brainer and wasn't worth a scintilla of fret.

What had been holding me up was gear binding. My lathe has been crashed into oblivion numerous times in its life, to the point that the idler shift gear LA-191 was completely missing, rendering the cross feed drive inoperable. The bearing bracket LA-196 was broken and had been welded; a fairly common malady for these lathes. Both the remaining miter gears LA-188 and 189 that drive the idler show the scars of battle, having some fairly significant tooth deformation in spots. The very nice used idler gear I purchased did not mesh well with 188. A bit of sleuthing showed a couple of things. First, as Mister Ed posited, there is indeed a bend in the pin that the idler shift gear rides on, but I don't think it is enough to cause a problem. Second, 188 did have a couple of well dented teeth that caught every time. Imagine a crash violent enough to break brackets, bend gear teeth way out in the apron, and bend the idler shift pin?! A little profiling with a file and 188/191 run nice and smooth. Certainly nothing to stew over for 6 months! So... very quickly, we are here;

Lots of juggling trying to get all this stuff together, as anyone who has ever done it knows. The biggest problem with aprons is you can't see what the hell you are doing back there. The last thing I snugged down was the LA-196 bearing bracket, and the next problem became apparent; the lead screw won't turn.

Loosen the bolt that holds the bracket to the apron and it turns fine. Tighten it again, and it binds. Pretty dang hard to see anything back there, but looking in all the way from past the change gear area shows the bearing bracket cocking upward when the bolt is snugged, jamming into the lead screw and bowing it upwards. I have no idea when the repair to LA-196 was done (although it appears to be done well), whether the lathe actually ever ran after that, or whether it has anything to do with this at all, but I now have to come up with a fix. :thinking:

Right off the top of my head, I can think of two ways. The easiest thing to do would be to open up the hole in the apron to allow for some adjustment, but I'm not sure that is the best way. The other would be to tear it all back apart again and attempt to set up the bracket on the mill such that I could change the angle of the mounting surface a bit. The difficulty in actually doing that accurately (how to measure how much?) is nudging me toward the inelegant fix, even though I dislike the thought quite a bit.

One thing I will say is that it won't take me another 6 months to decide. Gotta stay ahead of Tom, after all.

One thing I will say is that it won't take me another 6 months to decide. Gotta stay ahead of Tom, after all.