-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rotary table and chuck help

- Thread starter Mark_f

- Start date

- Joined

- Nov 27, 2012

- Messages

- 7,854

If you use a front mount chuck that has the same amount of monting holes as your rotary table has slots, then that's an easy way of course. But if not, melsdad made a style of adapter that would work in your case.

http://www.hobby-machinist.com/showthread.php/20573-Rotary-table-Chuck-mounting-plate?p=178115&viewfull=1#post178115

http://www.hobby-machinist.com/showthread.php/20573-Rotary-table-Chuck-mounting-plate?p=178115&viewfull=1#post178115

F

f350ca

Forum Guest

Register Today

Mark, I mounted a cheap 8 inch rear mount 3 jaw on my 8 inch rotary by simply drilling through the outer edge (carefully avoiding the scroll). With careful spacing you can sneak a four bolt pattern between the 3 jaws. Direct mounting saves the height of an adaptor plate. Can snap a photo if your interested.

Greg

Greg

Mark, I mounted a cheap 8 inch rear mount 3 jaw on my 8 inch rotary by simply drilling through the outer edge (carefully avoiding the scroll). With careful spacing you can sneak a four bolt pattern between the 3 jaws. Direct mounting saves the height of an adaptor plate. Can snap a photo if your interested.

Greg

Yes, I am interested as i want to stay as low as possible. I not sure the chuck has clearance enough though.

Thanks ,

Mark

If you use a front mount chuck that has the same amount of monting holes as your rotary table has slots, then that's an easy way of course. But if not, melsdad made a style of adapter that would work in your case.

http://www.hobby-machinist.com/showthread.php/20573-Rotary-table-Chuck-mounting-plate?p=178115&viewfull=1#post178115

WOW! That is so simple, I been racking my brain and never thought of that. (maybe I can blame the stroke for inducing a bout of stupidity)

Thank you so much for the idea,

Mark

F

f350ca

Forum Guest

Register Today

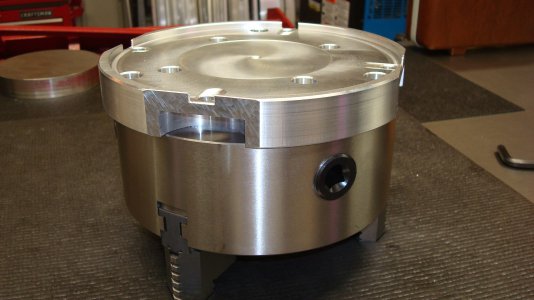

Mark, here's a couple of shots of the chuck, its just sitting on the table for the photo op. 3/8 bolts fit the rim of this chuck but even 1/4 inch would hold it. I have a rod somewhere with a morse taper to fit the rotary table hole, it extends up through the chuck, close the chuck on it before bolting it down gets it fairly well centred. If I remember right I centred the chuck on the mill table and used the dro to lay out the holes, but that rod would have worked with the table rotated too.

Had planned to get socket head cap screws to fasten it down but the hex head work so never got round to it.

Just another idea.

Greg

Had planned to get socket head cap screws to fasten it down but the hex head work so never got round to it.

Just another idea.

Greg

- Joined

- Dec 15, 2014

- Messages

- 285

It is amazing that the simplest approach is often the best. Not having the additional space of a adapter plate is a huge advantage on most vertical mills. The previous posts of the other adapters is a nice way to adapt as well as that gives one the option to be able to bolt the chuck directly to the mill table if you don't need the rotary function and need more daylight. Great ideas everyone.

Darrell

Darrell

A

Andre

Forum Guest

Register Today

I have a Grizzly 4" table, and used a Craftsman 109 4" 4 jaw chuck. It has through holes in the chuck which made things simple. Will be saving this thread in case I get a larger table and chuck, thanks for the pictures everybody  )

)