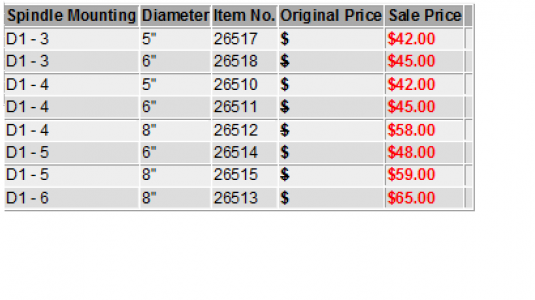

Hi everyone: I've got an 8 inch RT that appears to be a knock-off of the one Dark Zero posted. It has 4 slots. My Cutmaster 13x40 lathe has a 6 inch 3 jaw, and an 8 inch 4 jaw cam lock chuck. I'd like to be able to use them on the RT. I am confused as to what the designations for the adapters indicate. I've been out to the CDCO Machinery Corp site someone recommended below, but the designations confuse me. I was under the impression that the number after the D-1 designation (1,2,3,4....) indicated the chuck size. Evidently not. Here is the chart they provide. Which of these would work (if any)? Thanks, guys.