- Joined

- Dec 3, 2013

- Messages

- 1,849

My version of a spindle stop for my PM-1440GT lathe with 2" spindle bore.

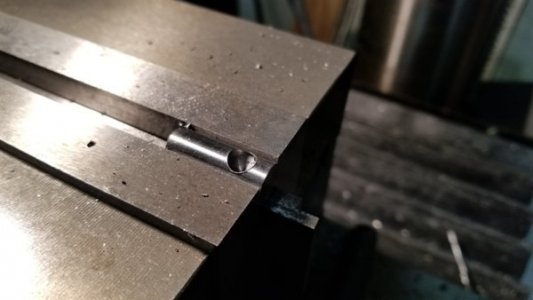

I have been using this stop for a while. Made from Delrin, a 3/* aluminum rod and 3/16" & 1/4" drill rod at the ends. It is held in place by one of the outboard spider setscrews and adjusted with a 1/4-20 setscrew. Something I made up quickly for a job. Works okay but a bit of a pain to quickly install and adjust.

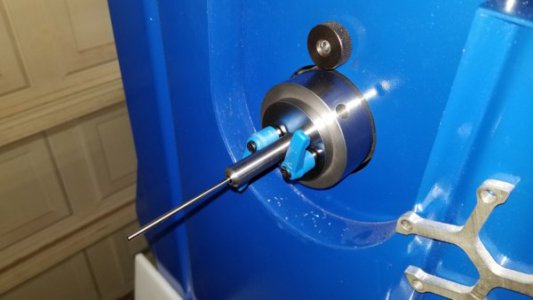

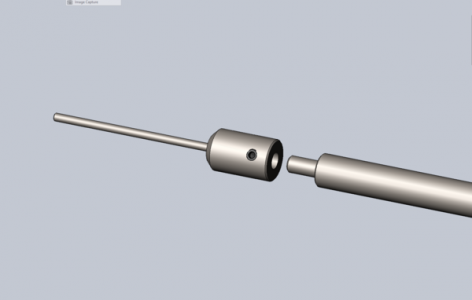

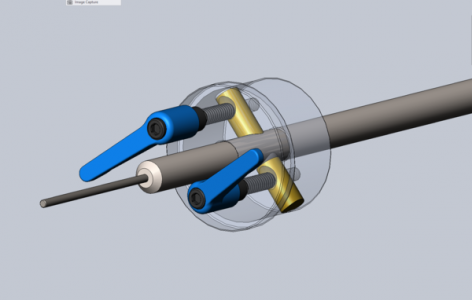

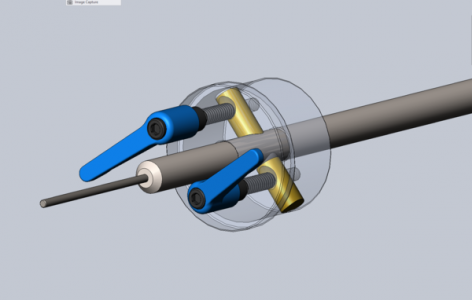

I decided to make one that was tool-less to install and adjust. The adapter is made from 2-1/4" 1018 cold rolled steel. The adapter is held in place by a pin that is engaged by a 1/4-20 adjustable handle. Same for the stop rod lock. The stop rod and lock pins are made from O-1 drill rod.

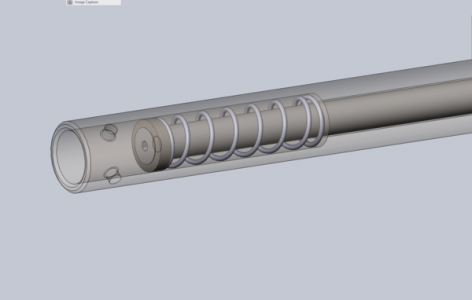

Cad Model showing how pins are engaged.

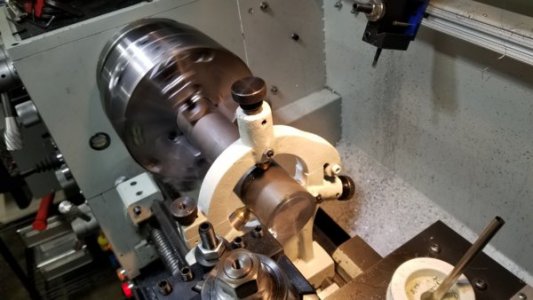

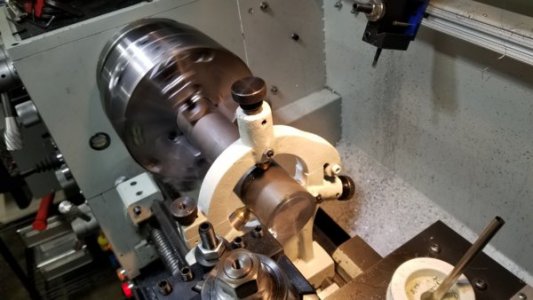

Truing up the stock in the 3-jaw prior to facing and drilling.

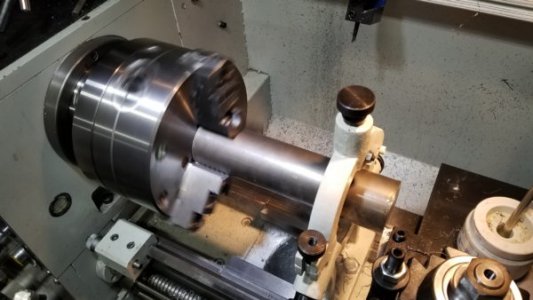

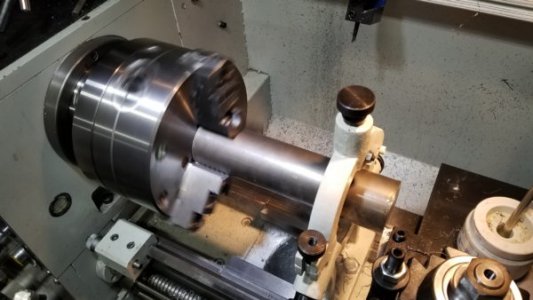

Stock supported in the steady for facing and drilling. I would have done the turning in the steady but I discovered it would not open more than 2" so I had to remove the collar the holds the top finger and lock the finger with a set screw. Okay for facing and drilling but sketchy for turning.

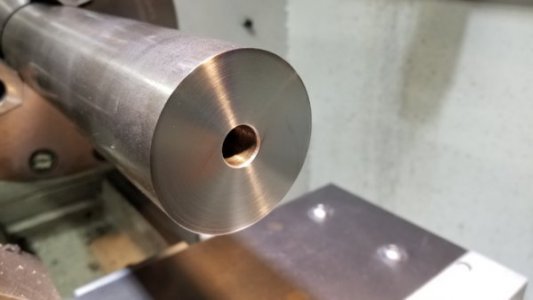

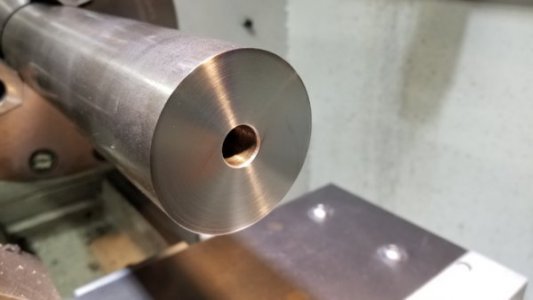

Used a larger center drill to make a flat for the live center.

A quick hit with some 220 paper.

Chamfer tool. Everyone should have one!

Stock was cut off in the horizontal band saw and then faced to size. Brass shim stock protects the turned and semi-polished area from being marred by the chuck jaws.

The adapter was turned 0.002" undersized for a slip fit into the outboard spider.

To be continued.....

I have been using this stop for a while. Made from Delrin, a 3/* aluminum rod and 3/16" & 1/4" drill rod at the ends. It is held in place by one of the outboard spider setscrews and adjusted with a 1/4-20 setscrew. Something I made up quickly for a job. Works okay but a bit of a pain to quickly install and adjust.

I decided to make one that was tool-less to install and adjust. The adapter is made from 2-1/4" 1018 cold rolled steel. The adapter is held in place by a pin that is engaged by a 1/4-20 adjustable handle. Same for the stop rod lock. The stop rod and lock pins are made from O-1 drill rod.

Cad Model showing how pins are engaged.

Truing up the stock in the 3-jaw prior to facing and drilling.

Stock supported in the steady for facing and drilling. I would have done the turning in the steady but I discovered it would not open more than 2" so I had to remove the collar the holds the top finger and lock the finger with a set screw. Okay for facing and drilling but sketchy for turning.

Used a larger center drill to make a flat for the live center.

A quick hit with some 220 paper.

Chamfer tool. Everyone should have one!

Stock was cut off in the horizontal band saw and then faced to size. Brass shim stock protects the turned and semi-polished area from being marred by the chuck jaws.

The adapter was turned 0.002" undersized for a slip fit into the outboard spider.

To be continued.....