- Joined

- Nov 6, 2021

- Messages

- 47

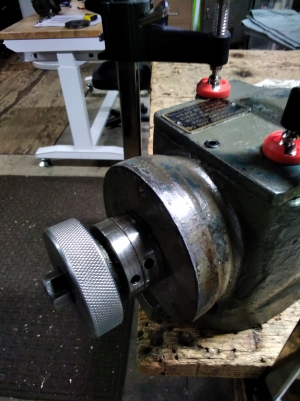

Greetings. I recently acquired a VN12 and I've never used these machines before. The machine was setup with a horizontal arbor and from what I can tell about the machine's work history, that machine could have been setup that way for years.

Anyway, I couldn't remove the 5v shank arbor when I disassembled it. I tried going through the gears to find a "low" gear where I couldn't turn the spindle by hand but couldn't find one. I have the cutter head removed with the arbor still in the spindle. I've tried putting an adjustable on the flats on the arbor and a wrench on the hex section of the draw tube but I'm afraid to use to much force.

I assume you turn the draw tube counter clock-wise? Do I need to tap on the top of the hex portion to get it out? What should I do?

Thanks

Anyway, I couldn't remove the 5v shank arbor when I disassembled it. I tried going through the gears to find a "low" gear where I couldn't turn the spindle by hand but couldn't find one. I have the cutter head removed with the arbor still in the spindle. I've tried putting an adjustable on the flats on the arbor and a wrench on the hex section of the draw tube but I'm afraid to use to much force.

I assume you turn the draw tube counter clock-wise? Do I need to tap on the top of the hex portion to get it out? What should I do?

Thanks