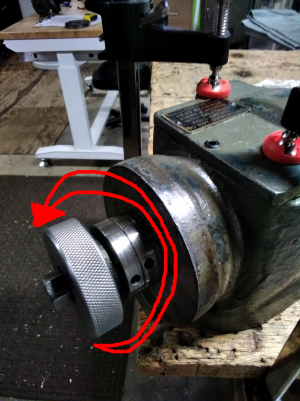

pictures are helpful. inboard of the drawtube knurled section, you've got what look to be two discs with holes in the side, which may be some sort of jam nut? if you put a close-fitting pin or punch in those holes, does that give you leverage to turn them?

if it were me, I would possibly do some of the following:

- clamp the cutters on the arbor between pieces of wood in a strong vise, which should immobilize the arbor well

- consider an impact driver on the hex at the end of the drawbar

- or unscrew the arbor nut, and potentially use the keyed shaft of the arbor to immobilize the arbor

the spindle dogs don't need to come out, unless they are convenient to give you leverage on the arbor.

if it were me, I would possibly do some of the following:

- clamp the cutters on the arbor between pieces of wood in a strong vise, which should immobilize the arbor well

- consider an impact driver on the hex at the end of the drawbar

- or unscrew the arbor nut, and potentially use the keyed shaft of the arbor to immobilize the arbor

the spindle dogs don't need to come out, unless they are convenient to give you leverage on the arbor.