Hi Kaveman,

I bought the ball screw/nut from here (excellent quality):

https://www.cnc4you.co.uk/Ballscrew...llnut-RM1605-C7-16mm?search=ballscrew 1605-c7

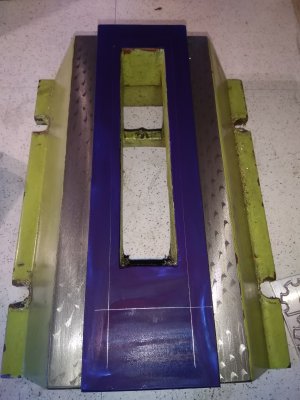

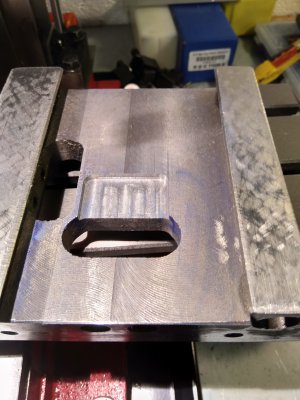

My first attachment shows the (considerable) metal removal I had to make to the top of the saddle to fit the X screw and nut. The nut itself also required considerable size reduction.

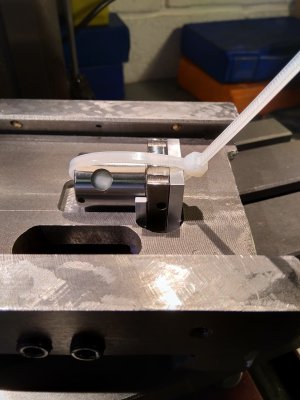

To attach the ball nut I made a fixing plate in a similar manner to AdyNI (above - I have copied AdyNI photo) except that where as AdyNI's saddle sit on top the the ball nut flange my fixing plate fitted flush on the end. I will see if I can find a photo. In the first picture you can see the flat top edge of the fixing plate for the Y-Axis poking out.

The metal easily ground down with a hand held drill and an everyday ball shaped grinding bit.

I completed the construction to the point of getting the X and Y working. But it took a great deal of going back and forth.

So - yes a 16mm will fit but it is mm tight on the underside of the table.

14mm - if the parts are available would be a much more comfortable fit. But I do wonder if 14mm will be strong enough for the Z axis? Maybe a shorter screw pitch would be better? Or use 14 for X and Y and 16 for Z.

I used an arduino with CNC shield and Chilipeppr (browser based) controller.

It worked well but (due to the low power drivers on the CNC shield) jerked a lot under load. Thus I concluded that the X, Y conversation was mechanically sound, but my electrical setup was not powerful enough and would have to upgrade to more power solution - and thus more money.

I started working on the Z axis but came to a stop because I ideally required the milling machine to be able to make the parts - thus I had to dis-assemble and re-assemble a couple of times. I did not continue but would say that the Z axis was likely to be the easiest part as it did not require any adaptation to the machine itself - just construction of some new parts.

Bottom line is, Yes it can be done especially if you have a second milling machine, but you do need to remove quite a lot of metal off the saddle for the X-axis - and a lot of patience.

What next? - I decided that if I am going to invest the money in the more powerful electrical driver setup (probably £500+) I would rather buy the WM-16 to make it worth while (not an easy financial jump I admit) - for several reasons: A heavier more stable machine for the quick direction changes that a CNC makes; I would have a second mill to make the parts (keep the WM-14 and sell it afterwards); 16mm would fit with limited adaptation; There is already a lot of WM-16 conversion information on the Web - the WM-16 is almost the same as: BF30 = G0704 = AMA25 = PM-25 (don't quote me on this).

I'll see if I can whip up some more photos.