- Joined

- Sep 14, 2016

- Messages

- 63

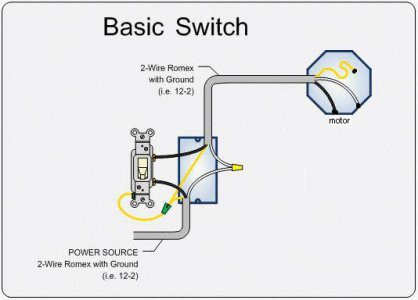

Okay, so I have a simple electrical job to do but I am not very familiar with wiring. Have a small lathe, its supposed to be powered by a Sears Craftsman 1/3 hp motor. The motor already has a power cord, but no switch. How can I convert the motor over to a switch so that I can power it on and off? I already have the metal electrical box and the on/off switch. Can anyone offer any advice, I just want to get this done correctly.

Thanks,

Tim

Thanks,

Tim