- Joined

- Apr 23, 2018

- Messages

- 6,840

Well, it doesn’t.

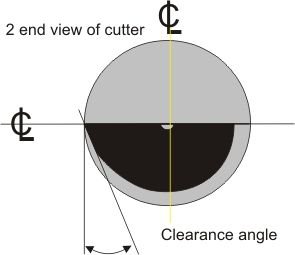

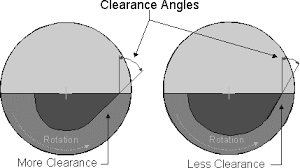

I am surprised actually. I gave it more relief on the opposite side of the dovetail.

It cuts a vertical wall. I was feeding .005” at a time, chips were coming off but no angled cut!

Back to the drawing board.

It has to be the back side cutting the vertical wall. I’ll give more relief.

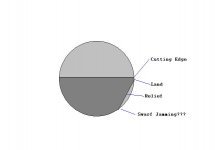

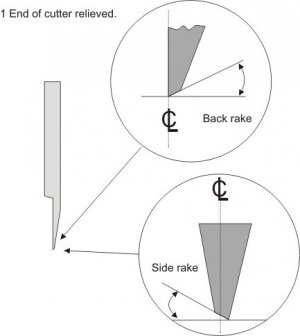

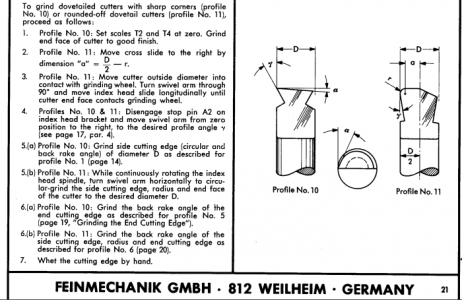

I knew this when you posted your cutter photo, but I feel like you are one who learns by doing, so I kept my mouth shut. Now that you know what you missed on the cutter, here are some pics and a copy of the Deckel manual, which goes into detail on how to make working cutters.