- Joined

- Sep 20, 2021

- Messages

- 152

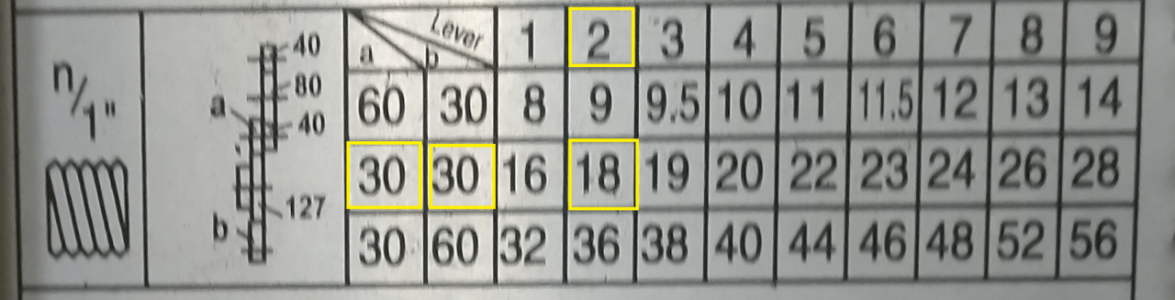

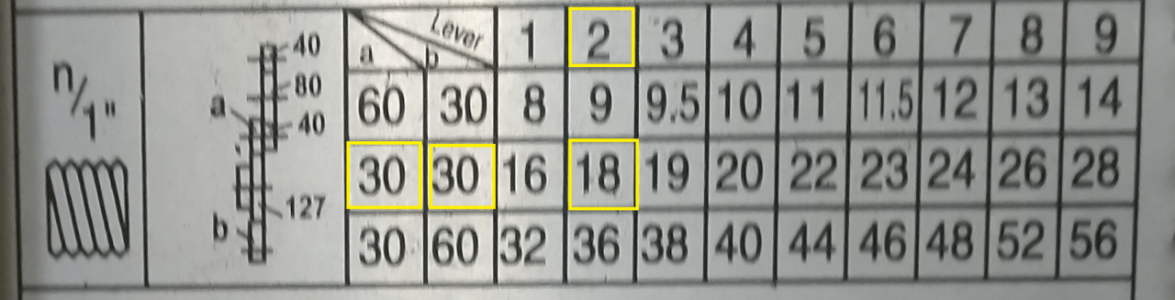

I'm unable to get the desired 18 tpi from my Jet Lathe (JET BD920N). I've set the gears as shown in the picture. I double checked them tonight by carefully counting the teeth on the small ones (a=30 and b=30). The lever is set to Position #2 as indicated on the chart... with those settings the thread it produces looks more like 32 tpi... it's very fine.

I have the machine on the slowest speed, though I don't think the speed selection matters, since the gears make movement relative.

I don't understand what I'm doing wrong. I was able to produce 18tpi before (as discussed this thread: https://www.hobby-machinist.com/threads/trying-to-make-sense-of-the-threading-charts.99688)

I have the machine on the slowest speed, though I don't think the speed selection matters, since the gears make movement relative.

I don't understand what I'm doing wrong. I was able to produce 18tpi before (as discussed this thread: https://www.hobby-machinist.com/threads/trying-to-make-sense-of-the-threading-charts.99688)