I've had really good luck with San Ou chucks from CME Tools. CME is based here in Madison Heights, MI and is the importer for the San Ou chucks that get sold by many other retailers. I've been to their place multiple times and they've let me walk around in back to see the massive pallets of stuff...it's pretty amazing. The guy who I've dealt with the most says the big boss started importing machine tools from China 30+ years ago and they've just bought a much larger warehouse because they've run out of room. They told me the San Ou chucks come from the largest chuck manufacturing company in China who makes chucks for some of the big names.

I have their 8" 3-jaw adjustable structure on one of my lathes and it was no problem getting it down to half a tenth runout on a 1" carbide end mill I used to check. I'm sure it won't stay at half a tenth if I change diameter stock, but even if it's a couple of tenths it's fine for what I do...if I need better it's time for the 4-jaw anyway. I'm getting ready to buy one of their 6" 3-jaw adjustable structure chucks for a lathe I'm refurbishing.

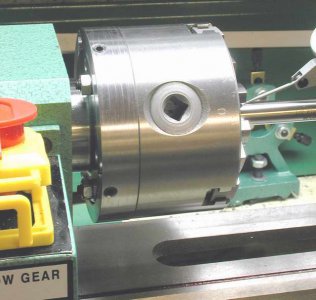

I did a mix and match with the 8" by using a fully machined Shars backplate so I didn't have to deal with drilling the bolt holes...worth the slight difference in price. That's actually my only "complaint" with CME is that the backing plates for the adjustable structure chucks are only semi-machined meaning very thick and no bolt holes. That gives you options, but makes it a bit messier, slower job to fit one. Here's the 6" CME chuck on eBay...it's worth checking both the CME website and their eBay store as sometimes the price will be better on one or the other.

6" - 3 JAWS Self-Centering precision adjustable structure chuck, 6"/167mm w. D1-4, D4 semi-finished adapter plate. TWO PCS TONGUE AND GROOVE REVERSIBLE HARDENED top & bottom JAWS. Back mounting recess dia: 80mm.

www.ebay.com