-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ATC for Benchtop Mill

- Thread starter vertcnc

- Start date

- Joined

- Aug 23, 2013

- Messages

- 970

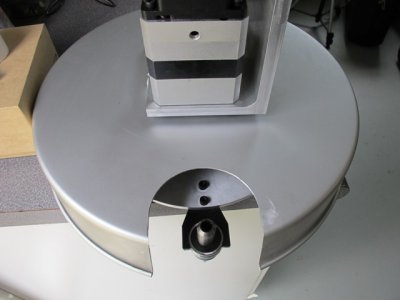

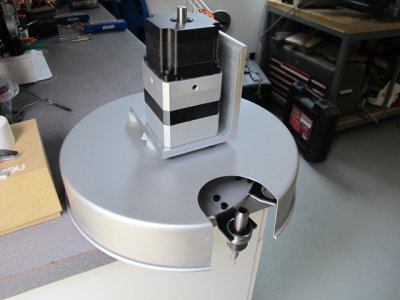

I am working on an automatic tool changer for my RF 45 and MTW MD001 mills. It will utilize the Tormach holders. Thought I would share a few pics. May build a few extras if there is any interest.

View attachment 56736View attachment 56737View attachment 56738

You should make the tool holders from a sacrificial material (nylon, plastic, etc.), if your machine has a crash, the tool holders will break and not damage the spindle bearings or the carousel. Also mount a physical home switch so you can index it or use an absolute rotary scale. This will save you time when homing the machine. Do you have an air source to blow out your spindle? If there is a chip on the tool and is not blown out, it will affect accuracy. Alignment pins on your tool holder instead of a lot of bolts will also help when there is a crash, the pins will align new tool holders and the bolts just hold them into place, if you don't want to use pins, machine a guide block or use a key for alignment. Tim

You should make the tool holders from a sacrificial material (nylon, plastic, etc.), if your machine has a crash, the tool holders will break and not damage the spindle bearings or the carousel. Also mount a physical home switch so you can index it or use an absolute rotary scale. This will save you time when homing the machine. Do you have an air source to blow out your spindle? If there is a chip on the tool and is not blown out, it will affect accuracy. Alignment pins on your tool holder instead of a lot of bolts will also help when there is a crash, the pins will align new tool holders and the bolts just hold them into place, if you don't want to use pins, machine a guide block or use a key for alignment. Tim

The tool holders are held in place by nylon bolts, in the event of a crash holder will break free from carousel. Proxy switch located on carousel for referencing home. Air blast located inside umbrella. Still work in progress will share as I move along.

- Joined

- Apr 20, 2013

- Messages

- 210

Is that a cake pan??

What type of collet system will your RF45 have in order to use these tools?

What type of collet system will your RF45 have in order to use these tools?

Is that a cake pan??

What type of collet system will your RF45 have in order to use these tools?

Yes, Umbrella is fabricated from aluminum baking pan. I have since found some stainless to fabricate it from. After protype is tested probably will change. Tooling and collets are the Tormach TTS tooling.