Hi guys, I have another newbie question for ya…

Note: By “large” stock I mean larger diameter than spindle bore of my particular lathe, which is quite small…just have to put things in perspective…

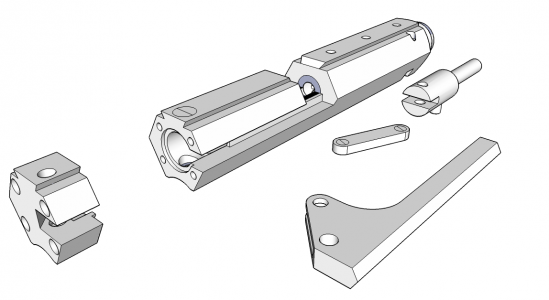

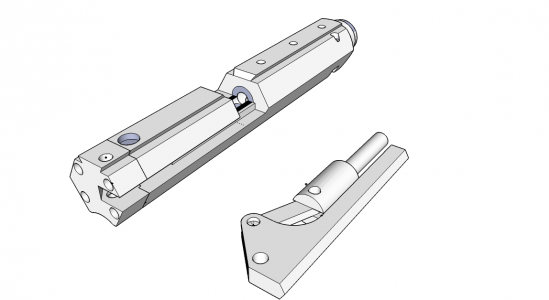

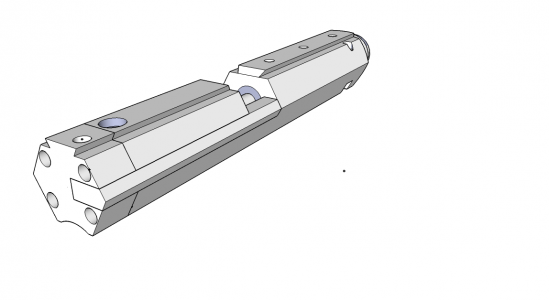

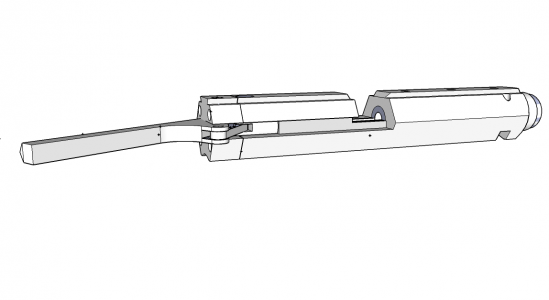

First, a little background on the project I’m getting ready to tackle - I designed a trick side lever breech for my .25 cal airgun (another hobby of mine) and have pretty much figured out how to go about machining almost everything using only my 7 x 12 mini lathe, but admit that I’m stumped on how to perform the very first step...boring a full length (i.e- 6.5” long), 7/16” diameter hole in some 1” aluminum hex bar.

Now, I know on a bigger lathe you would normally just mount the hex bar in the lathe chuck, put your extra long 7/16” bit in the drill chuck in tailstock and have at it (after center drilling first, of course), but my wee lathe only has a ¾” spindle bore and 10.5” of carriage travel so there goes that idea out the window. I could (theoretically) do the operation in reverse - mount the drill bit in lathe and hex bar in milling attachment and feed the bar into the spinning bit, but I’m afraid the hole will end up veering off-center, effectively making it nothing more than a paperweight with an off-centered hole.

Any ideas, providing it’s even possible on such a small machine???

Worst case scenario (and the direction I think I'm heading), I have a machinist/gunsmith buddy who lives about an hour from me who can perform the operation quite easily and quickly on his much bigger 12 x 28 (1.5” spindle bore) so I’m not really stuck, was just hoping to be able to do 100% of the project on my own for a change…kind of a “personal milestone” sorta thing for me…lol

Note: By “large” stock I mean larger diameter than spindle bore of my particular lathe, which is quite small…just have to put things in perspective…

First, a little background on the project I’m getting ready to tackle - I designed a trick side lever breech for my .25 cal airgun (another hobby of mine) and have pretty much figured out how to go about machining almost everything using only my 7 x 12 mini lathe, but admit that I’m stumped on how to perform the very first step...boring a full length (i.e- 6.5” long), 7/16” diameter hole in some 1” aluminum hex bar.

Now, I know on a bigger lathe you would normally just mount the hex bar in the lathe chuck, put your extra long 7/16” bit in the drill chuck in tailstock and have at it (after center drilling first, of course), but my wee lathe only has a ¾” spindle bore and 10.5” of carriage travel so there goes that idea out the window. I could (theoretically) do the operation in reverse - mount the drill bit in lathe and hex bar in milling attachment and feed the bar into the spinning bit, but I’m afraid the hole will end up veering off-center, effectively making it nothing more than a paperweight with an off-centered hole.

Any ideas, providing it’s even possible on such a small machine???

Worst case scenario (and the direction I think I'm heading), I have a machinist/gunsmith buddy who lives about an hour from me who can perform the operation quite easily and quickly on his much bigger 12 x 28 (1.5” spindle bore) so I’m not really stuck, was just hoping to be able to do 100% of the project on my own for a change…kind of a “personal milestone” sorta thing for me…lol

) that I would have less problems with a "wandering" bit by having it (bit) held stationary in tailstock and your work piece spinning in lathe. Something about "allowing the bit to follow the path of least resistance", which in my mind made perfect sense so I've been running with it ever since.

) that I would have less problems with a "wandering" bit by having it (bit) held stationary in tailstock and your work piece spinning in lathe. Something about "allowing the bit to follow the path of least resistance", which in my mind made perfect sense so I've been running with it ever since.