I am now playing with titanium. (Well, it is called 6-4 which I think means 6%Al and 4%V). I have noted two interesting features:

-Bill

- On the HF 4x6 bandsaw (with a sensibly good blade) I can cut it. And the "saw dust" (doesn't quite seem to be swarf to me) is different from other metal filings. The filings interlock with each other as they fall to the floor. And they collectively form a loose mat. Move some of it and several inches away it is interlocked and the filings move too. It pulls apart easily, but something surprising and unexpected.

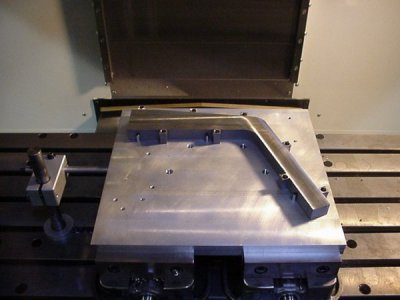

- On the mill, on 1" wide bar, 1 mil depth of cut, 1" feed per 10 seconds, with a 3" 5-carbide blade facer at 2500 rpm--whoa! A regular Christmas display of bright white sparks fly everywhere. Beautiful but I stopped the feed pretty quickly--flying fire isn't of much interest in the shop. If I brought it down to 800rpm no fire. Feed slowly enough and the finish is ok (not shiney through). The sparks lasted long enough to land on Ti swarf. No ignition there. The color was much whiter than the slight yellow sparks I get with some steels. And not the brilliant blue-white of burning magnesium.

-Bill