- Joined

- Nov 8, 2012

- Messages

- 783

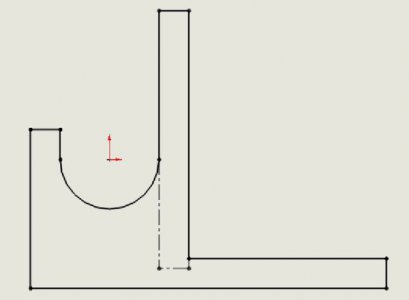

Is the gear teeth area a separate piece ???

I see 5 or 6 little indents on the side, almost looks like pin holes or could be places used for holding from the original manufacturing.

Even if not, I wonder if one could machine a piece with new teeth, mill out the old teeth (depending on thickness) and key, pin, or screw the new teeth to the old piece. The two outside teeth seem untouched so might be able to leave those in place for added support and strength for the new material.

If possible, this would seem an easier, cheaper solution.

I see 5 or 6 little indents on the side, almost looks like pin holes or could be places used for holding from the original manufacturing.

Even if not, I wonder if one could machine a piece with new teeth, mill out the old teeth (depending on thickness) and key, pin, or screw the new teeth to the old piece. The two outside teeth seem untouched so might be able to leave those in place for added support and strength for the new material.

If possible, this would seem an easier, cheaper solution.