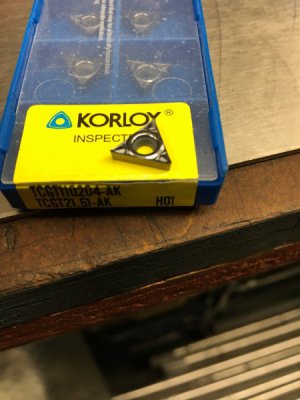

More eBay and Harbor Freight shopping. Picked up some small boring bars (6 mm and 7 mm diameter) that take CCMT 21 bits. Recall the boring bars being something like $6-$8 each. Picked up 20 inserts too for under $8 per 10.

Picked up a batch of 10 new Guhring 1/4" parabolic drills. Impulse buy for $31.

I have a 12-ton HF shop press and swapped out the hand-pump bottle jack for an air over hydraulic. The press has served me well over the years, but the design at the load points isn't the greatest. The bottle jack pushes up on a piece of tubular steel which in turn pushed down on the base of the jack which has the arbor on the bottom. Steel rods connect the bottle jack base to the top tubular reaction surface. The nuts on the rods had severely deformed the tubing, not to the point of pulling completely through, but I wasn't in the mood for any surprises. A better design would be a piece of plate or channel to carry the load from the middle of the square tubing to the sides.

I went the easier route and bought a 20-ton press. The 12-ton air over hydraulic is on the new press, so shouldn't be bending this one. I'll repurpose the angle from the 12-ton press and make a rolling rack for stock storage.

My 12-ton press

Bent tubing, curious that a 12-ton rated

press would get this bent up with the

a 12-ton bottle jack . . . Safety factor in the design?!?!

New 20-ton press with the 12-ton jack

Bruce

![20181229_184641[1].jpg 20181229_184641[1].jpg](https://www.hobby-machinist.com/data/attachments/240/240811-a7d24487dc86a88f3f10797af7ea7061.jpg)

![20181229_184641[1].jpg 20181229_184641[1].jpg](https://www.hobby-machinist.com/data/attachments/240/240811-a7d24487dc86a88f3f10797af7ea7061.jpg)