- Joined

- Jun 12, 2018

- Messages

- 712

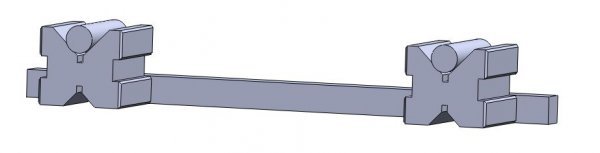

High sensitivity import levels are available for less than $100.

8'' Precision Machinist Level Engineers Bar Inspection Block 0.0005''/10'' | eBay

Find many great new & used options and get the best deals for 8'' Precision Machinist Level Engineers Bar Inspection Block 0.0005''/10'' at the best online prices at eBay! Free shipping for many products!www.ebay.com

Ok, I cancelled my Amazon order and bought this instead. It'll take a month to get over here, though. Probably has to be shipped from China

I'll be happy with .0005 over 10"