-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New machines for me!

- Thread starter Deano

- Start date

2-3 weeks out for delivery due to DRO install. After machine installations then new flooring is going in. I bought some of that Race Deck type flooring because when I pulled up the carpeting and scraped up the tile underneath, there was a thin layer of old adhesive that's still a little tacky. It would have been a mess to try to get up. After that, then the pictures are absolutely coming!Welcome to the cult...errrrmmm, I mean club!

Congrats on the machines. You are going to love them. Pictures when they come, otherwise you will get kicked off of the forum.

That's really nice of them, but I've already got someone for that! LOL!Give these guys more time Deano and they will be more than happy to spend your money!

Not too much overhang off the front of the table? That's kind of my concern with the DX line. The 4" compared to the 6" is only about an inch shorter. The 3600V is quite a bit shorter, but way more money!I concur with the 6" vise recommendation. I wrestled with the decision when I got my 8x35 mill. Decided on the 6" Kurt and couldn't be happier (well, I will be happier when I make a speed handle for it--the Kurt handle is a PITA).

Last edited:

- Joined

- Sep 2, 2013

- Messages

- 378

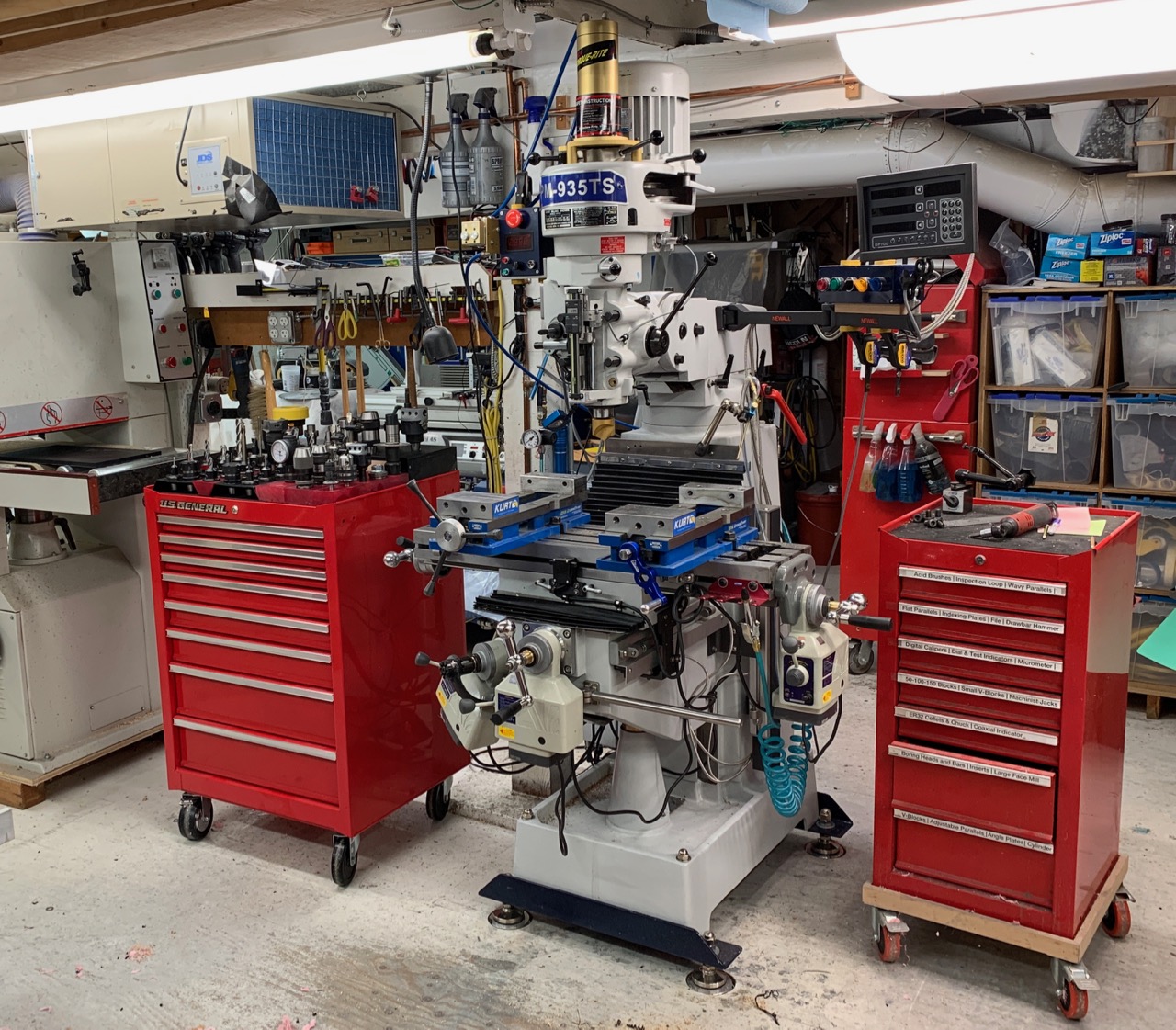

Here is the Kurt 6DX on my PM935. Works for me. I don't have that lathe back there any more, upgraded to the 1440GT. So we have the same setup. Congratulations.....

- Joined

- Dec 26, 2015

- Messages

- 2,079

Congrats. The Kurt 6-inch is what you want on the PM935. I routinely run two DX6 on my 935:

There's plenty of room for the 6-inch version. If you're at all interested in the upgrades I did to my mill, click here.

There's plenty of room for the 6-inch version. If you're at all interested in the upgrades I did to my mill, click here.

Look how clean that floor is! Love it!Here is the Kurt 6DX on my PM935. Works for me. I don't have that lathe back there any more, upgraded to the 1440GT. So we have the same setup. Congratulations.....

View attachment 309939

Dave< I notice you're using the center slot for your T nut. Would it interfere with the Y travel if you used the rear most slot?Congrats. The Kurt 6-inch is what you want on the PM935. I routinely run two DX6 on my 935:

View attachment 309940

There's plenty of room for the 6-inch version. If you're at all interested in the upgrades I did to my mill, click here.

- Joined

- Nov 14, 2016

- Messages

- 3,007

I have a 5" Kurt clone on my 6x24" mill, I think a 4" would be a better fit for it but it works. If a 5" works on my little mill I can't imagine you would have an issue with a 6" vise on a 9x35" table.

The 6" vise also seems to be much more common than 4" or 5" vises, so you can find better deals on them sometimes even cheaper than 4" since the DX4 and DX6 are practically the same price. I see a lot of used 6" vises, but few 4" and never have found a particularly good price on a used Kurt 4".

The 6" vise also seems to be much more common than 4" or 5" vises, so you can find better deals on them sometimes even cheaper than 4" since the DX4 and DX6 are practically the same price. I see a lot of used 6" vises, but few 4" and never have found a particularly good price on a used Kurt 4".

- Joined

- Dec 26, 2015

- Messages

- 2,079

Dave< I notice you're using the center slot for your T nut. Would it interfere with the Y travel if you used the rear most slot?

Depends on what you mean my "interfere". Remember, on a mill like this the head can be positioned via the ram, so you effectively have two Y-axis travels: the head position and the XY table position. I just took a few photos of my vise setup, and I think these will explain the mounting. If you mount the Kurt in the center T-slot, it hangs over the back just about the same distance as is taken up by the DRO encoder/scale. So in this position the Y-travel is not restricted. If you mount it in the rear-most T-slot, then you will loose about 2-inches of Y travel. To maximize rigidity, I like to keep the fixed jaw close to the back of the XY table and the ram pulled in.

Hope this helps.