- Joined

- Feb 9, 2017

- Messages

- 5,254

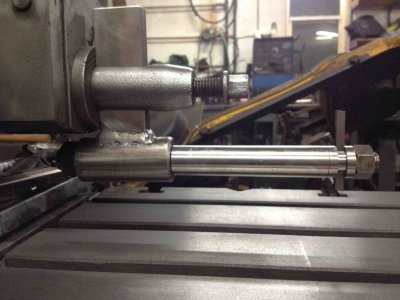

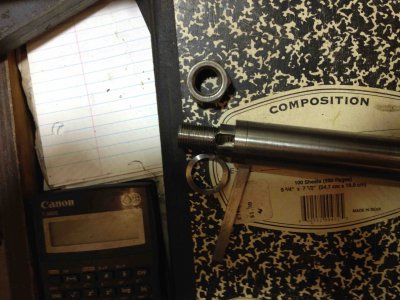

I've been struggling with exactly the same feeling. I have to keep reminding myself I don't have the setup, materials and experience a good toolmaker has. Everything is on the fly and engineering to stock. I have also contemplated making something like the #46 but I think if it ever comes down to it I'll make a threaded shank with a shoulder that can bolt into my #39 holder. It kills me several years before I got my Atlas 7b I was in a local antique store and amongst some lathe tool holders there was a #46 minus a bar. I remember picking it up and thinking what the heck is this for? Don't remember the price but I didn't buy it of course.Thanks Martin. I know I’m a bit slow. It took me a few days to do this. I was thinking that tool and die makers much be incredibly skilled and efficient to do their jobs. I’m in awe of their skill levels every time I’m in the shop and getting aggravated at the amount of time it’s taking me to do a simple job as above.