- Joined

- Sep 7, 2019

- Messages

- 674

I'm kinda takin a day off from the workshop.

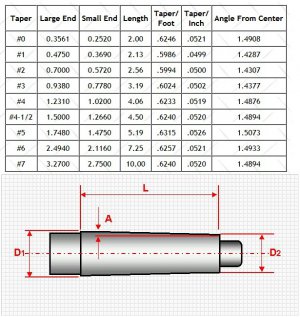

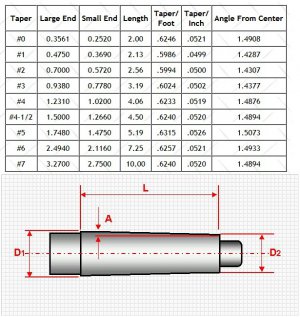

I was going to try to make a morse taper but I don't have any appropriately sized steel. I found a good resource of dimensions though...

Maybe next week I'll find something else to work on. I've got an old toolpost grinder that needs a belt. Anyone know anything about making a drive belt from a strip of leather? It's a flat belt of course.

I was going to try to make a morse taper but I don't have any appropriately sized steel. I found a good resource of dimensions though...

Maybe next week I'll find something else to work on. I've got an old toolpost grinder that needs a belt. Anyone know anything about making a drive belt from a strip of leather? It's a flat belt of course.