- Joined

- Sep 1, 2020

- Messages

- 1,592

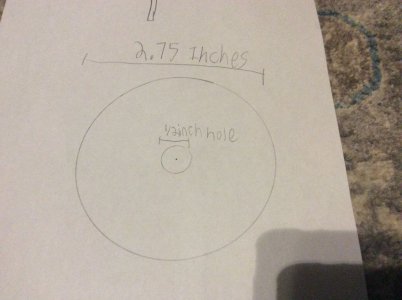

Hello would any one be able to make me a simple reducer

2.5 inches across can be 5 thouthands under size but only a few over preferably under size.

0.125 inches thick can be from 1/8 inch thick to 3/16 inch thick.

1/2 inch hole in the center can be drilled or reamed if you like to over do

I can supply 3/16 of an inch thick aluminum plate that I can supply but I would have to use a hacksaw to cut it or you could cut it if you have a band saw. This is to reduce the size of bore In a gear so that I can use it on my power hacksaw build.

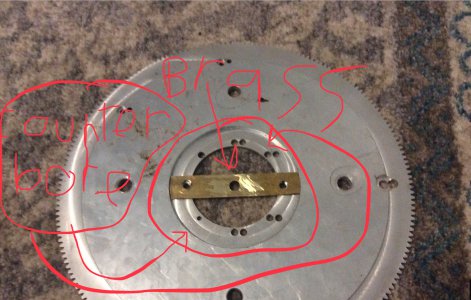

It is for the big aluminum gear that I will use in thes project.

www.hobby-machinist.com

www.hobby-machinist.com

2.5 inches across can be 5 thouthands under size but only a few over preferably under size.

0.125 inches thick can be from 1/8 inch thick to 3/16 inch thick.

1/2 inch hole in the center can be drilled or reamed if you like to over do

I can supply 3/16 of an inch thick aluminum plate that I can supply but I would have to use a hacksaw to cut it or you could cut it if you have a band saw. This is to reduce the size of bore In a gear so that I can use it on my power hacksaw build.

It is for the big aluminum gear that I will use in thes project.

Homemade power hacksaw

I want a bandsaw but no space want a power hacksaw but no money but with metal I was given along with some gears I’m starting to build a power hack saw . I have no u channel but some 2.5in by 3in angle that I will use. I have some more metal but it is 3in by 3in by 72in by 1/4in hot rolled each...

www.hobby-machinist.com

www.hobby-machinist.com