Hello everyone,

I managed to find a DoAll DH-612 Surface Grinder locally at a really good price.

The biggest issue I had was how the heck to move it with just an engine hoist and some good straps?

I tried to find some information on the internet from others who may have moved one but no joy.

There are no holes for a pipe or steel bar for lifting it like on a Harig 612.

The user manual says to only move it with a forklift from the bottom of the base cabinet, well that wasn't possible for me since I have a limited budget and no access to a forklift.

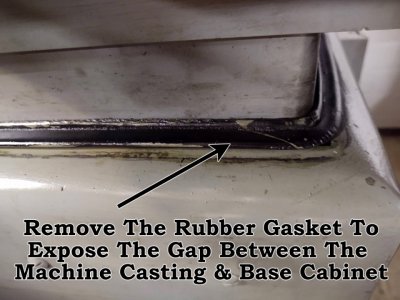

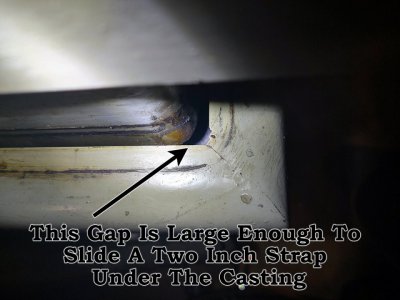

After a good close look, I discovered that there is a gap between the casting of the bottom of the machine and the opening at the top of the base cabinet, there is also about a one inch gap between the bottom of the casting and the top of the base cabinet where it sits, there are four feet about one inch thick on the bottom of the casting which left plenty of room for a heavy duty strap.

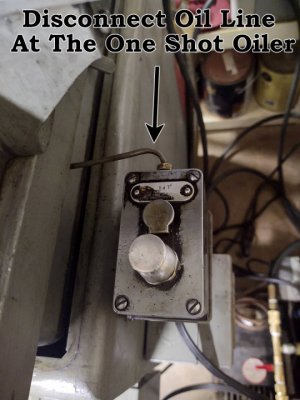

I had to remove the rubber gasket/seal between the casting and the base cabinet to get the strap in and under the front portion of the machine casting, I also had to disconnect the wiring from the motor at the motor starter switch on the side of the base cabinet as well as disconnect the oil line from the one shot oiler system so the machine could be separated from the base cabinet.

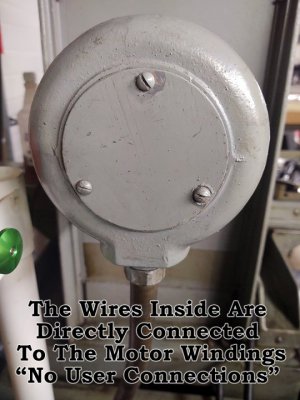

Note: The motor wiring cannot be disconnected at the motor housing as the wires in the sealtite conduit are connected directly to the motor windings.

I really did not want to lift this thing by the spindle and motor for fear of messing it up in some way.

The saddle is just sitting on the main casting and only held down by the Y axis lead screw and nut so lifting it by the saddle isn’t a good idea either.

Also, I decided that it would be best to remove the table and set it to the side as it is only held on by gravity and a toothed traverse belt.

The trick to moving it was to wrap a good heavy duty main lifting strap around the column just under the motor at the back with a half knot on the front above the spindle while keeping the lifting loops at the ends of the strap even with each other to hook onto the engine hoist chain hook.

Then wrap another strap from under the front of the casting and over the half knot on the main lifting strap to keep the main lifting strap cinched tight around the column.

I used a third strap from the chain hook on the engine hoist to the back of the casting to prevent the top of the machine from tipping backward, I didn’t use the motor to support to third strap, one of the attached photos shows where a strap hook can be placed on the back at the bottom of the machine casting.

See attached photos.

This method may not be the best but it seemed to be the safest way without causing any damage and it just worked out for me.

I just wanted to post some information about this to hopefully help someone else needing to move one of these particular surface grinders with limited means.

This site and other sites have been very helpful in the past so giving back what I can seems to be the right thing to do and I do enjoy helping folks out when I can.

I managed to find a DoAll DH-612 Surface Grinder locally at a really good price.

The biggest issue I had was how the heck to move it with just an engine hoist and some good straps?

I tried to find some information on the internet from others who may have moved one but no joy.

There are no holes for a pipe or steel bar for lifting it like on a Harig 612.

The user manual says to only move it with a forklift from the bottom of the base cabinet, well that wasn't possible for me since I have a limited budget and no access to a forklift.

After a good close look, I discovered that there is a gap between the casting of the bottom of the machine and the opening at the top of the base cabinet, there is also about a one inch gap between the bottom of the casting and the top of the base cabinet where it sits, there are four feet about one inch thick on the bottom of the casting which left plenty of room for a heavy duty strap.

I had to remove the rubber gasket/seal between the casting and the base cabinet to get the strap in and under the front portion of the machine casting, I also had to disconnect the wiring from the motor at the motor starter switch on the side of the base cabinet as well as disconnect the oil line from the one shot oiler system so the machine could be separated from the base cabinet.

Note: The motor wiring cannot be disconnected at the motor housing as the wires in the sealtite conduit are connected directly to the motor windings.

I really did not want to lift this thing by the spindle and motor for fear of messing it up in some way.

The saddle is just sitting on the main casting and only held down by the Y axis lead screw and nut so lifting it by the saddle isn’t a good idea either.

Also, I decided that it would be best to remove the table and set it to the side as it is only held on by gravity and a toothed traverse belt.

The trick to moving it was to wrap a good heavy duty main lifting strap around the column just under the motor at the back with a half knot on the front above the spindle while keeping the lifting loops at the ends of the strap even with each other to hook onto the engine hoist chain hook.

Then wrap another strap from under the front of the casting and over the half knot on the main lifting strap to keep the main lifting strap cinched tight around the column.

I used a third strap from the chain hook on the engine hoist to the back of the casting to prevent the top of the machine from tipping backward, I didn’t use the motor to support to third strap, one of the attached photos shows where a strap hook can be placed on the back at the bottom of the machine casting.

See attached photos.

This method may not be the best but it seemed to be the safest way without causing any damage and it just worked out for me.

I just wanted to post some information about this to hopefully help someone else needing to move one of these particular surface grinders with limited means.

This site and other sites have been very helpful in the past so giving back what I can seems to be the right thing to do and I do enjoy helping folks out when I can.

Attachments

-

DoAll DH612 Web Photo.jpg47.5 KB · Views: 216

DoAll DH612 Web Photo.jpg47.5 KB · Views: 216 -

Lifting Strap Locations.jpg116.2 KB · Views: 196

Lifting Strap Locations.jpg116.2 KB · Views: 196 -

Base.jpg84.2 KB · Views: 201

Base.jpg84.2 KB · Views: 201 -

Rubber Gasket.jpg108.6 KB · Views: 187

Rubber Gasket.jpg108.6 KB · Views: 187 -

Gap for strapping.jpg99.4 KB · Views: 179

Gap for strapping.jpg99.4 KB · Views: 179 -

Disconnect oil line.jpg70.9 KB · Views: 178

Disconnect oil line.jpg70.9 KB · Views: 178 -

Motor Wiring.jpg78.5 KB · Views: 172

Motor Wiring.jpg78.5 KB · Views: 172 -

Back Of Machine Casting.jpg132 KB · Views: 191

Back Of Machine Casting.jpg132 KB · Views: 191