-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adjustable Surface grinder dresser

- Thread starter Janderso

- Start date

- Joined

- Nov 3, 2022

- Messages

- 66

I worked in a grinding shop for a few years. This is how you do it if the dresser is t permanently attached to the machine.I don’t like that I have to move the SG wheel a significant amount to dress in the middle of a job.

I saw an adjustable dresser on a Youtube video.

Here is my version. It works great, I tried it out.

The base is from an extra surface gauge I had laying around. It locks up on the magnet rock solid.

- Joined

- Mar 26, 2018

- Messages

- 8,407

I like donutsRemember L over D like a boring bar . A large bar will cut but it will also chatter when the length is too large .

Time to make the donuts here .

- Joined

- Mar 26, 2018

- Messages

- 8,407

I would love to have a factory dresser in the wheel housing.I worked in a grinding shop for a few years. This is how you do it if the dresser is t permanently attached to the machine.

That would be convenient

- Joined

- Mar 26, 2018

- Messages

- 8,407

I received a suggestion from Benmychree (John York).

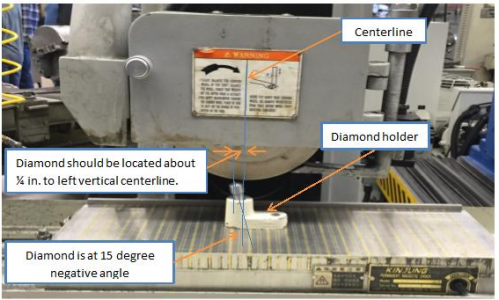

John suggested I introduce the dresser at an angle. 90 degrees to the wheel not the spindle.

I measured the angle on the short standard cast iron dresser. It has an 18 degree angle.

I'm thinking of welding up the existing hole on my dresser and redrilling at the expected angle.

When John speaks, I listen.

John suggested I introduce the dresser at an angle. 90 degrees to the wheel not the spindle.

I measured the angle on the short standard cast iron dresser. It has an 18 degree angle.

I'm thinking of welding up the existing hole on my dresser and redrilling at the expected angle.

When John speaks, I listen.

- Joined

- Mar 26, 2018

- Messages

- 8,407

- Joined

- Mar 26, 2018

- Messages

- 8,407

Many of us have had no formal training.

Setting this angle up I assumed I should angle the dresser toward the wheel on the “safe” side of rotation.

According to some videos I have watched, there seems to be some inconsistencies.

SG‘s that have built in dressers are at 12:00 straight into the wheel or at 2:00 or so, ??

I found this in an instruction manual. Angled away from the wheel on the safe side.

What method do you use?

Setting this angle up I assumed I should angle the dresser toward the wheel on the “safe” side of rotation.

According to some videos I have watched, there seems to be some inconsistencies.

SG‘s that have built in dressers are at 12:00 straight into the wheel or at 2:00 or so, ??

I found this in an instruction manual. Angled away from the wheel on the safe side.

What method do you use?

Attachments

- Joined

- Nov 19, 2018

- Messages

- 252

On my Acer 12x24, the built-in is 12:00. The manual states to use a chuck-mounted one for best results, and there is some flex / chatter likely from the built-in one (their words - I have not compared the results). Funny - I saw a YT video with the adjustable mounts yesterday & was thinking of making one too. MMMMmmmmmm.... donuts.......

- Joined

- Mar 26, 2018

- Messages

- 8,407

About 14 minutes in he just slides the head over, adjusts the height of the adjustable dresser, a quick dress then back to grinding.I saw one the other day where the upright shaft was inclined at an angle towards the front. This gave more clearance above the diamond between the dresser upright and the wheel guard. It was in this video featuring Ellie Price.

This style is available commercially ($125+) but I think I may start over.I like the design and it looks very stable.

This is the guy I was watching when I decided to look through my stock to come up with my version.

Thanks for posting this, I hadn’t watched much if the video.