- Joined

- Mar 25, 2013

- Messages

- 4,617

I learned something amazing today that I probably should have known years ago. Perhaps all y'all already know this but I will enlighten those who do not.

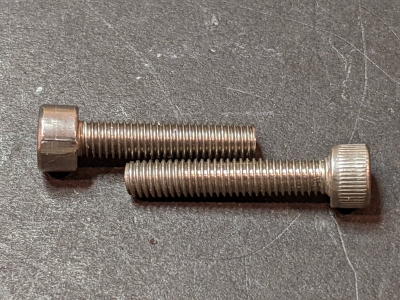

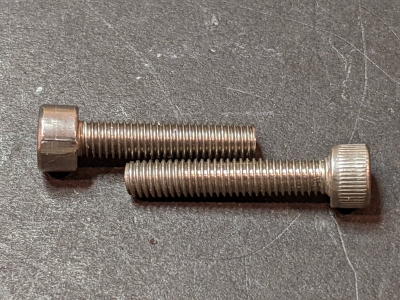

A 10-32 and and M5 coarse screw are almost identical! I mean so close that I cannot always tell them apart with a caliper and a thread gauge. Depending on the thread class they may even mate with the incorrect opposite and work just fine.

After some research I have determined the following:

The major dimeter of a 10-32 is 0.183 to 0.189". The major diameter of an M5 typically measures near this range or minimally larger. My stock is 0.190!

The pitch of a 10-32 in mm is .794mm. The pitch of a M5 coarse is .800. These are too close to see visually. If you engage a metric screw in a 10-32 socket it will make multiple revolutions before binding. For a short thread like a nut you may not even notice.

Also, the socket on my 10-32 cap screws accept a 4mm hex key perfectly!

As far as I know, other sizes are not nearly this close and never interchangeable.

M5 and a 10-32

Don't mix up your stock!

Robert

A 10-32 and and M5 coarse screw are almost identical! I mean so close that I cannot always tell them apart with a caliper and a thread gauge. Depending on the thread class they may even mate with the incorrect opposite and work just fine.

After some research I have determined the following:

The major dimeter of a 10-32 is 0.183 to 0.189". The major diameter of an M5 typically measures near this range or minimally larger. My stock is 0.190!

The pitch of a 10-32 in mm is .794mm. The pitch of a M5 coarse is .800. These are too close to see visually. If you engage a metric screw in a 10-32 socket it will make multiple revolutions before binding. For a short thread like a nut you may not even notice.

Also, the socket on my 10-32 cap screws accept a 4mm hex key perfectly!

As far as I know, other sizes are not nearly this close and never interchangeable.

M5 and a 10-32

Don't mix up your stock!

Robert

Last edited: