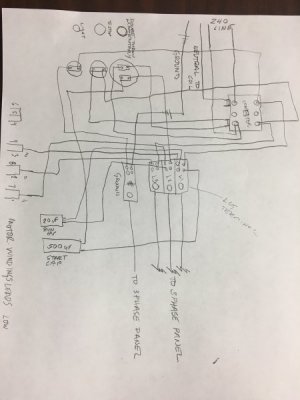

Hello everyone, first post. I built a rotary phase converter and all seems well except when the converter is started up the 10 hp motor shaft locks up I can’t turn it by hand until I turn off the converter. I tried moving the 3 phase wires around on the motor leads with no luck. I wired the motor for low voltage per the attached diagram.

I have not been able to balance the voltage yet due to the motor not generating the 3rd leg. The motor is brand new out of the crate ( see photos) 60 amp breaker at supply panel.

Any help will be greatly appreciated.

I have not been able to balance the voltage yet due to the motor not generating the 3rd leg. The motor is brand new out of the crate ( see photos) 60 amp breaker at supply panel.

Any help will be greatly appreciated.