- Joined

- Dec 3, 2013

- Messages

- 1,849

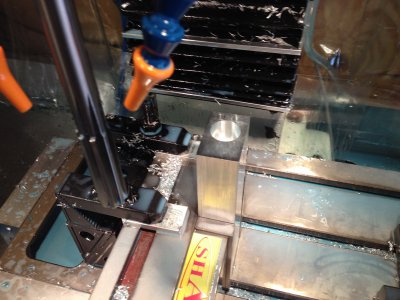

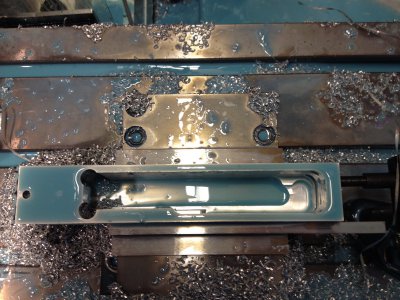

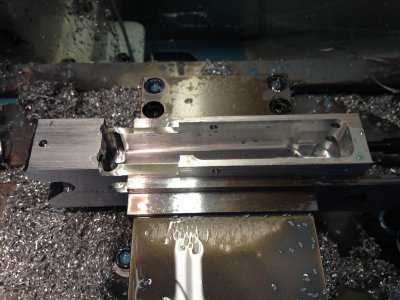

As a CNC learning project I decided to do a custom 1022 receiver. I figured I would post a thread about the good, bad and ugly as I go through the process.

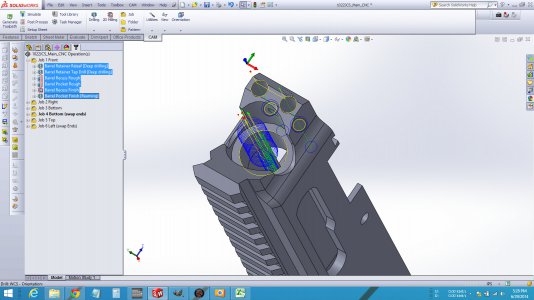

I am using Solidworks for the CAD and a free add-on CAM program called HSM Express. HSM Express is only 2.5D. I'm not endorsing one program over another. As a mentor for a high school robotics team, we use Solidworks for our CAD and I get a yearly licence for free. Using the free version of HSM was a no brainer. What I do like about HSM Express is that it is embedded in the CAD program.

For many years I used AutoCad to make 2D drawings for manual machining. When I first had the opportunity to use Solidworks a few years ago I was sold on the idea of modeling pats is 3D. I'm still very much a novice to Solidworks but projects like these really help build your skills.

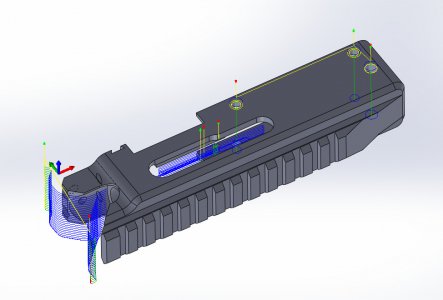

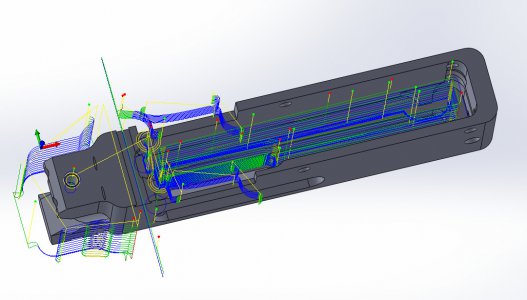

I have the CAD completed and the CAM tool paths generated for the main part of the receiver.

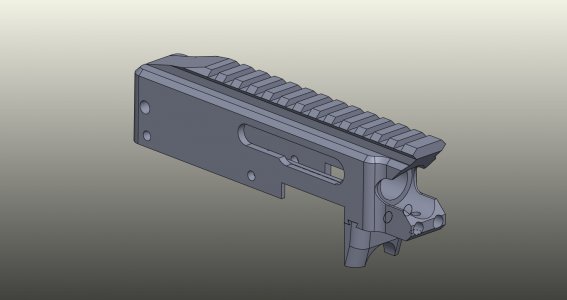

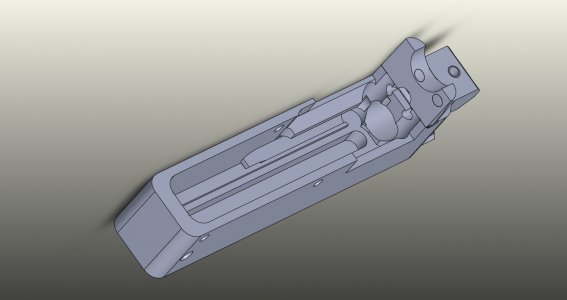

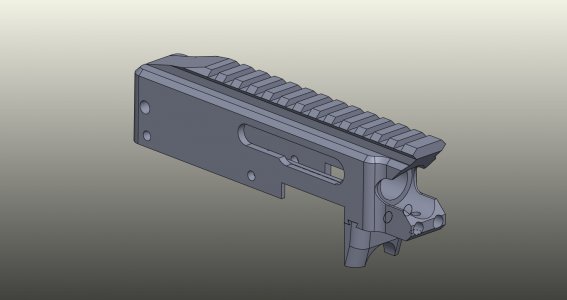

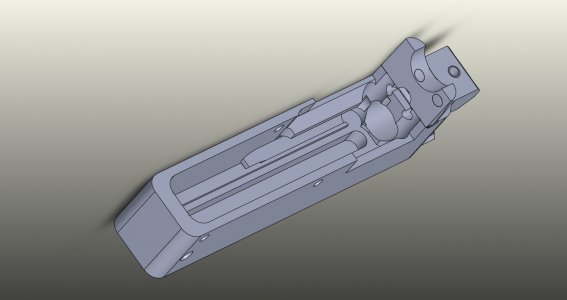

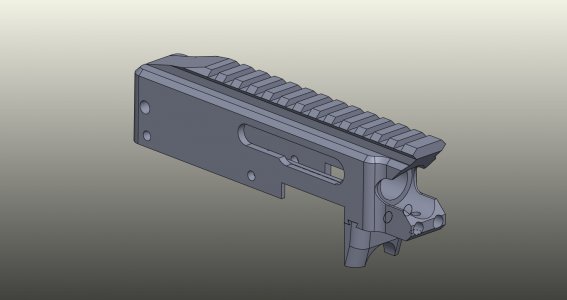

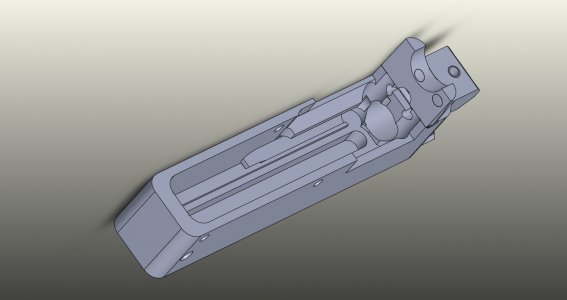

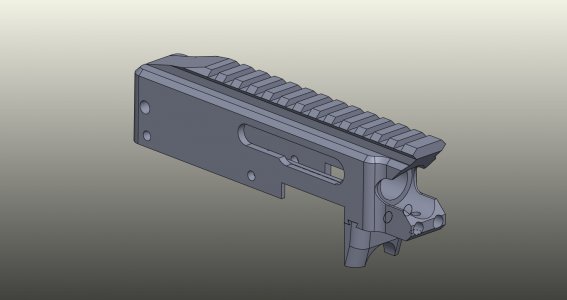

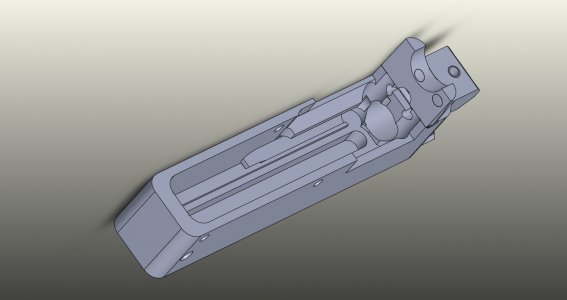

Here is a capture of the CAD model.

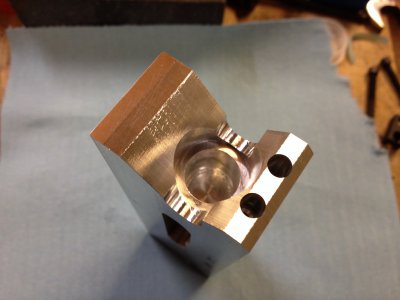

If look at the lower lug of the receiver you will see a dovetail joint. The OEM 1022 receiver is an aluminum casting which unfortunately does not simply translate to machining. Doing the receiver in two parts simplifies a number of operations. I will get into more detail about this when I do that operation.

To be continued.......

Jay

I am using Solidworks for the CAD and a free add-on CAM program called HSM Express. HSM Express is only 2.5D. I'm not endorsing one program over another. As a mentor for a high school robotics team, we use Solidworks for our CAD and I get a yearly licence for free. Using the free version of HSM was a no brainer. What I do like about HSM Express is that it is embedded in the CAD program.

For many years I used AutoCad to make 2D drawings for manual machining. When I first had the opportunity to use Solidworks a few years ago I was sold on the idea of modeling pats is 3D. I'm still very much a novice to Solidworks but projects like these really help build your skills.

I have the CAD completed and the CAM tool paths generated for the main part of the receiver.

Here is a capture of the CAD model.

If look at the lower lug of the receiver you will see a dovetail joint. The OEM 1022 receiver is an aluminum casting which unfortunately does not simply translate to machining. Doing the receiver in two parts simplifies a number of operations. I will get into more detail about this when I do that operation.

To be continued.......

Jay