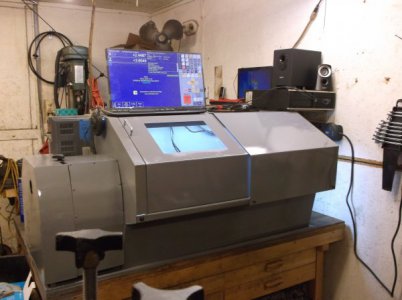

For the few days I have been working on the electrical and electronics.

after a sleepless night caused by no motion from the steppers, I found that the Centroid Acorn board defaults to 200000 steps per second in the setup wizard.

No problem right the closed loop driver say up to 200000kh... they lie

I had to go into the acorns main config and lower the frequency to 100000 steps per second for these drivers and everything works perfect now.

This will have no effect on the motion of the machine at 100000 steps per second, that over 300ipm.

thankfully there were some great videos by "Franco" and others on YouTube showing how to change the settings.

I also had to order a programming cable from China that hooks to my computers serial port to configure some extra features in the motor driver settings.

The VFD is a real HaunYang 4.0kw with an optional braking resister, not a knock off so it will have a 400w braking resister installed to stop spindle fast.

with this I'll be able to ridged tap, instant stop and reverse.

The spindle will stop instantly if either stepper misses steps, something is binding, e-stop is pressed or a crash happens.

Thanks for viewing

Steve