About a year ago, the clamp down ring that clamps the base of the compound to the cross slide table, cracked, right in the middle over the sight window where you view the angle markings. This was the thinnest portion of the clamp ring so it figures that it was the weakest. I decided that I would drill additional holes in the clamp ring to utilize four bolts instead of the just the two it had from the factory. My thought was that it would help to even out the clamping pressure and then the crack in the ring wouldn't really be a problem.

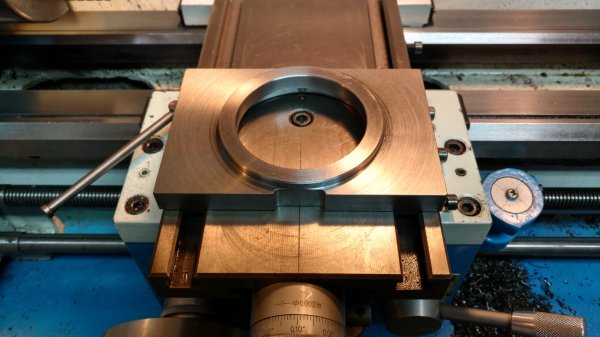

Fast forward to this week. I finally decided to make a new beefed up clamp down ring to replace the cracked one. I took my time and hit all the dimension I came up with. I am really happy with how things turned out so far on the new clamp ring. I just need to mill out the sight window and drill the bolt holes and it is done.

The issue is, that when I went to test fit the new clamp ring on the cross slide table, I noticed that the sides of the t-slots are cracked and are actually starting to break and be pulled upwards. I am now fearful that I have broken my cross slide table and it has to be replaced. I have already spoken with Matt about it. Since I modified the clamp ring, this isn't really a warranty issue, and I'm ok with that. He is getting me a price on a new table.

What I was wondering is if anyone else has ever had this issue on their lathe, whether or not it is a PM lathe? I am actually thinking about making a new table now as opposed to getting another factory table. I do wonder how a table made from steel will wear on the cross slide made of cast iron? Any input would be appreciated.

Thanks,

Fast forward to this week. I finally decided to make a new beefed up clamp down ring to replace the cracked one. I took my time and hit all the dimension I came up with. I am really happy with how things turned out so far on the new clamp ring. I just need to mill out the sight window and drill the bolt holes and it is done.

The issue is, that when I went to test fit the new clamp ring on the cross slide table, I noticed that the sides of the t-slots are cracked and are actually starting to break and be pulled upwards. I am now fearful that I have broken my cross slide table and it has to be replaced. I have already spoken with Matt about it. Since I modified the clamp ring, this isn't really a warranty issue, and I'm ok with that. He is getting me a price on a new table.

What I was wondering is if anyone else has ever had this issue on their lathe, whether or not it is a PM lathe? I am actually thinking about making a new table now as opposed to getting another factory table. I do wonder how a table made from steel will wear on the cross slide made of cast iron? Any input would be appreciated.

Thanks,