It's together and it works!

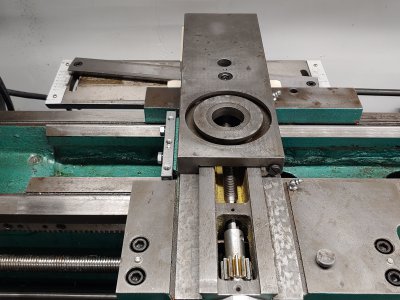

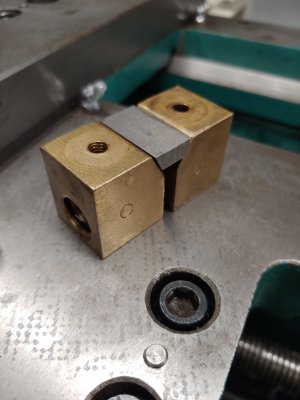

In the end the only mod I made was boring out the saddle + ordering the 13 tooth gear. And the feed screw nut needs to be drilled and tapped wherever it falls on your machine. I assembled everything and transfer punched it - works fine without any tight spots.

I haven't turned a taper yet need to do some final finishing but I can't see any reason why it would be junk. Will report back when I find out.

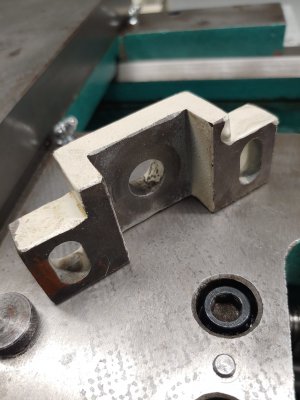

The only thing stopping you from turning very long steep tapers can be seen in the last photo attached - when set beyond 5 degrees the gib screw adjustment in the housing will hit the casting. I have not investigated to see if this is backwards or otherwise could be relieved - will cross that bridge one day when I unlikely will need to make a long steep taper.

In the end the only mod I made was boring out the saddle + ordering the 13 tooth gear. And the feed screw nut needs to be drilled and tapped wherever it falls on your machine. I assembled everything and transfer punched it - works fine without any tight spots.

I haven't turned a taper yet need to do some final finishing but I can't see any reason why it would be junk. Will report back when I find out.

The only thing stopping you from turning very long steep tapers can be seen in the last photo attached - when set beyond 5 degrees the gib screw adjustment in the housing will hit the casting. I have not investigated to see if this is backwards or otherwise could be relieved - will cross that bridge one day when I unlikely will need to make a long steep taper.