- Joined

- Jan 4, 2021

- Messages

- 912

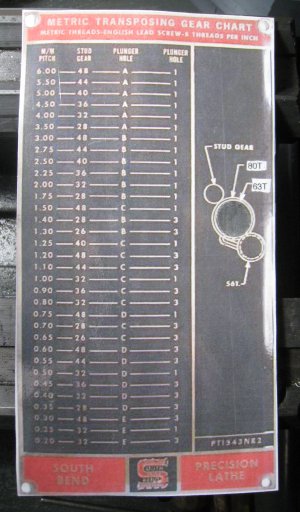

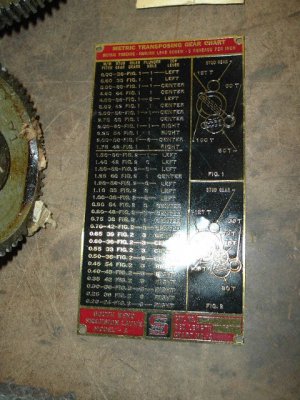

Did South Bend ever make a conversion kit to convert an imperial lathe to cut metric threads for the older (1941 era) 13" SINGLE tumbler QCGB lathes?

I'd like to, some day, look at making a set of gears for it, but I'd like to stay somewhat true to what SBL would have done. I would imagine it would need a new banjo, possibly.

I've searched for details but can't find anything. Not even an image of what the threading chart would look like.

Any help would be appreciated.

I'd like to, some day, look at making a set of gears for it, but I'd like to stay somewhat true to what SBL would have done. I would imagine it would need a new banjo, possibly.

I've searched for details but can't find anything. Not even an image of what the threading chart would look like.

Any help would be appreciated.