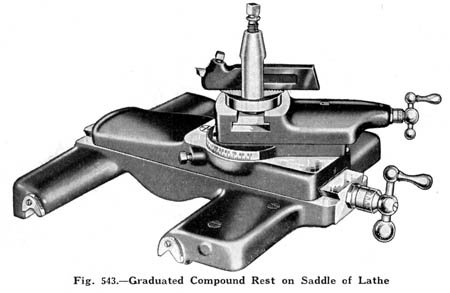

I have a Logan 200 lathe. When I went to adjust the compound, I couldn't find a wrench to fit the nuts that hold the compound to the cross-slide.A 9/16" wrench was too small, and a 5/8" wrench was too big, but would work. That led me to believe that the nuts are 19/32, an odd size.

I have a 19/32" wrench that was my dad's. It's an old wrench, marked"Controlled Steel." ( I'm glad the steel is controlled. I would hate for the atomic bonds to suddenly fail, and for the wrench to suddenly become energy. That would be bad for the lathe.)

Anyway, I just wanted to know if other Logan lathes used a 19/32" nut. Nothing in the catalog or parts list suggests a special size wrench for the compound.

Does anyone have a Logan lathe that uses 19/32" nuts? And why were 19/32" nuts made in the first place? Was there a specific reason for that particular size?

I'm going to continue to use the lathe as-is, but I can replace the nuts with a more common size if I want to.

Thanks for any help.

Rick W

I have a 19/32" wrench that was my dad's. It's an old wrench, marked"Controlled Steel." ( I'm glad the steel is controlled. I would hate for the atomic bonds to suddenly fail, and for the wrench to suddenly become energy. That would be bad for the lathe.)

Anyway, I just wanted to know if other Logan lathes used a 19/32" nut. Nothing in the catalog or parts list suggests a special size wrench for the compound.

Does anyone have a Logan lathe that uses 19/32" nuts? And why were 19/32" nuts made in the first place? Was there a specific reason for that particular size?

I'm going to continue to use the lathe as-is, but I can replace the nuts with a more common size if I want to.

Thanks for any help.

Rick W