- Joined

- Mar 31, 2015

- Messages

- 397

Hello everyone,

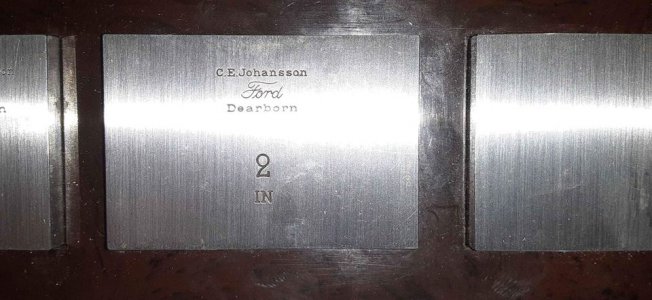

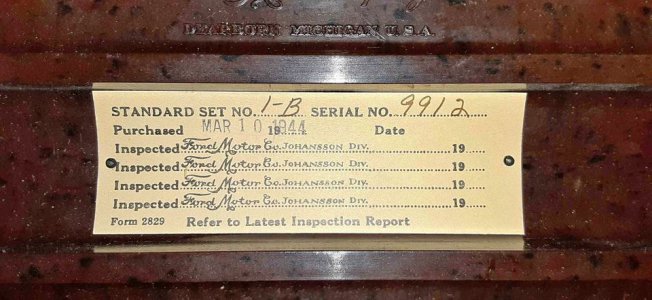

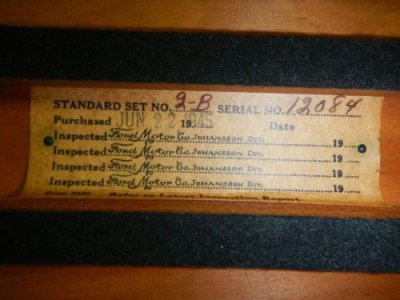

I've got an oppertunity to buy an 81 piece Ford C.E. Johanasson Gauge block set but I'm trying to determine the grade/tolerance to compare to more recent equipment. This will help me decide the value to me and what to offer.

I have faith that this old set (that is is very nice condition!) is of higher quality that a more recent workshop grade B (alt: 3 or AS2 depending on the standard) set, but I want to make sure.

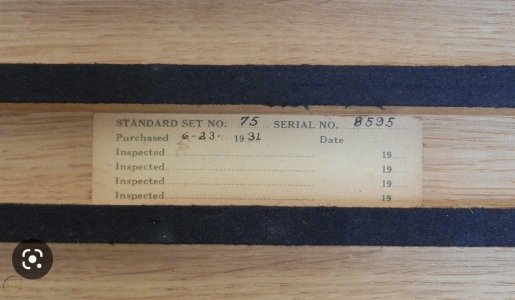

The only apparent information is on the tag: Standard Set No. 1-B, purchased 1944

Is the 1-B a grading? Or is it a product code/set number?

What would the be the lowest grade we could expect for Ford Jo blocks?

Thanks for your quick answers in advance! Wish me luck!

I've got an oppertunity to buy an 81 piece Ford C.E. Johanasson Gauge block set but I'm trying to determine the grade/tolerance to compare to more recent equipment. This will help me decide the value to me and what to offer.

I have faith that this old set (that is is very nice condition!) is of higher quality that a more recent workshop grade B (alt: 3 or AS2 depending on the standard) set, but I want to make sure.

The only apparent information is on the tag: Standard Set No. 1-B, purchased 1944

Is the 1-B a grading? Or is it a product code/set number?

What would the be the lowest grade we could expect for Ford Jo blocks?

Thanks for your quick answers in advance! Wish me luck!

I'm old and have plenty of useless junk .

I'm old and have plenty of useless junk .