- Joined

- Jan 9, 2023

- Messages

- 239

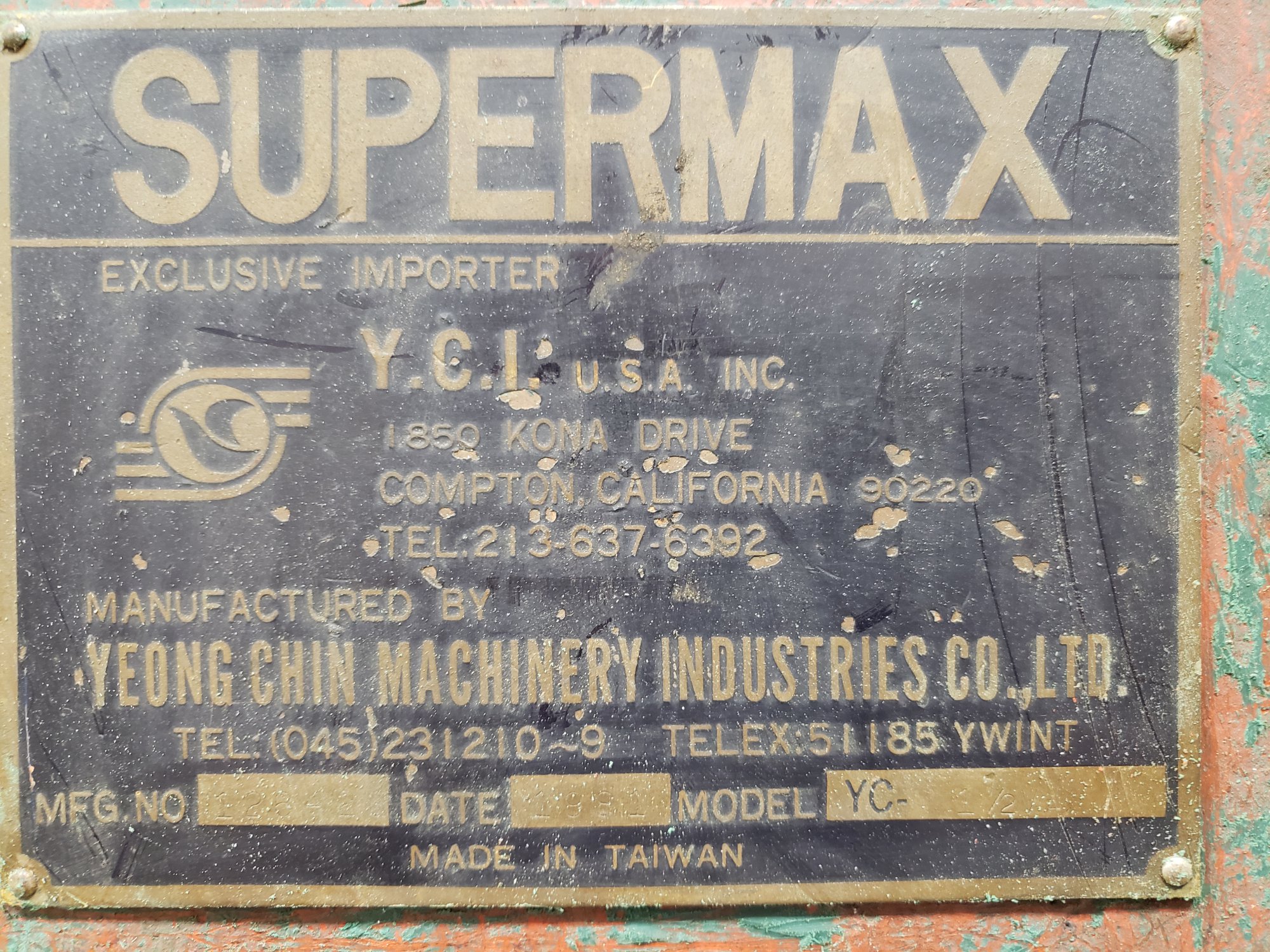

Howdy, submitted for your approval is a 1981 Supermax YC-1 1/2VA (BP S1 clone) mill made by Yeong Chin in Taiwan. A friend needed to make room for a better mill and gave it to me in pieces partially disassembled as he was in the middle of replacing the bearings and a couple small pinion gears. I've had it a couple years waiting to find time to get it up and running and just ordered parts and lube this week so I'll post a thread in projects covering it soon.

Last edited: