-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2013 POTD Thread Archive

- Thread starter HMF

- Start date

- Joined

- Apr 2, 2013

- Messages

- 230

Stern

Very nice looking job! Where does a guy get the rub on lettering! Is it individual letters? Thanks for sharing!

They are on sheets, have letters, numbers and a bunch of switch symbol ones. Got most many years ago, but the letter ones are still being sold at Office Depot and art stores.

- Joined

- Jan 11, 2013

- Messages

- 1,821

I. Love. This. Thread.

When I can't get to my shop, I love to see you guys getting into yours

Bernie

When I can't get to my shop, I love to see you guys getting into yours

Bernie

- Joined

- Jan 11, 2013

- Messages

- 1,821

Not a darn thing!!! And I am bummed about it too. I keep getting side tracked when I need to get out to the shop and get some cleaning done ASAP. Gonna need the room when I go get my 9X and bring it home. Was looking at a handi house to store just tools in, but them rascals are pretty spendy for a wooden box on skids. I can definitely build one for less than three grand, but swinging a hammer that much in the heat would probably do me in. Plus I want the instant solution to the problem delivered yesterday. Oh well I got three cases of glass bottles and a gross of caps in yesterday UPS so I can bottle the batch I have had in the ferm chamber for three weeks now. I'm hoping it turns out half way decent. It was my first run on the components I am building for my brew tower. So far so good. Just gotta finish the control panel and I will be in bidness

Robert! You brew? Damn, we gotta get together! My good friends in Maryland do too.. Pretty serious about it.

My friend just started the first Distillary in NJ since Prohibition! He is Distilling Rum! Good stuff too- Jersey Artisan Distillary!

Bernie

- Joined

- Jun 17, 2011

- Messages

- 2,063

I've been out in the garage for the last couple of weeks. I finally got around to pulling the engine out of my '77 Honda CB750 Four K. The top gear went out in the transmission, so I 'temporarily' replaced the bike with a 1981 GL1100 Interstate. That was 6 or 7 years ago. Goldwings are FUN. Anyway, guilt finally motivated me and I got the project going.

Turns out, the problem was a worn and bent centre gearshift fork. Honda no longer supports older bikes, so a used one was required. A friend in our Classic Motorcycle Club ( http://www.bcclassicmotorcycleclub.com/simplemachines/index.php ) had an engine with damaged case halves, so we split it last Friday evening. The required fork was factory perfect - still had the tool marks showing on the wear surfaces.

Long story short, I got the engine back in this afternoon. Just have to put in the carbs and a few other connections, and dispose of nearly a full tank of VERY old gas. We have a Collector License Plate category here that saves a bundle on insurance, as long as we NEVER ride the bike to work. (Costs about $20 a month for the 1100; $15 for a 750.) I'll apply for the plate for the 750 when it's looking original enough. That will make 3 on plates so far.

Turns out, the problem was a worn and bent centre gearshift fork. Honda no longer supports older bikes, so a used one was required. A friend in our Classic Motorcycle Club ( http://www.bcclassicmotorcycleclub.com/simplemachines/index.php ) had an engine with damaged case halves, so we split it last Friday evening. The required fork was factory perfect - still had the tool marks showing on the wear surfaces.

Long story short, I got the engine back in this afternoon. Just have to put in the carbs and a few other connections, and dispose of nearly a full tank of VERY old gas. We have a Collector License Plate category here that saves a bundle on insurance, as long as we NEVER ride the bike to work. (Costs about $20 a month for the 1100; $15 for a 750.) I'll apply for the plate for the 750 when it's looking original enough. That will make 3 on plates so far.

With all the awesome projects on this thread I'm a little embarrassed to add mine which is kinda lame but handy. I hate putting tools on the chip pan. I have a bad back and have to stoop to see past the carriage. I made an easily movable and removable tool tray and put some magnets on it just to keep my tools out where I can access them without much movement on my part.

This is a great idea, if it's designed to be moved to various machines it's even better still. I would add a movable shield attached with magnets to block chips from accumulating on it.

- Joined

- Jun 22, 2012

- Messages

- 1,552

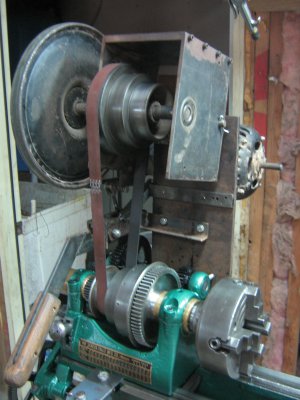

Very cool Bruce, nice looking lathe too! Any idea what the horse power of the motor is? Looking forward to seeing what the controller set up will be.

Very cool Bruce, nice looking lathe too! Any idea what the horse power of the motor is? Looking forward to seeing what the controller set up will be.

HP is 2.5 @ 3960 @150 Volts.

Controls are going to be simple, on/off switch, pot for speed control and a reversing switch. The treadmill controller is modified to eliminate the very slow start and stop, it will still use the slow start for a soft start feature but instead of taking 10 seconds to start it will be more like 2-3 seconds to reach full speed and the shutoff will be instant instead of taking 10 seconds to wind down. We also have a brake feature to stop the motor quicker but I won't have it stop to quick and toss the chuck off maybe a 1-2 second stop.

The Lathe had a barrel switch on the front, I think I will have the switch panel in the same place. I need to figure out a tach for it. I have a bicycle speedo I may try to use as a tach. anybody know of an inexpensive digital tach?

Brian

- Joined

- Oct 30, 2012

- Messages

- 960

Nothing major. Picked up a laser edge finder for nothing and was goofing with it seeing if it would work checking out alignments on my machines. Obviously not super precision but looks like it will get things reasonably close. Chucked up in my 6 jaw the dot nails the tip of the tailstock center pretty dead on. Adjusted QTP height till tool tip just breaks the beam. Anyone else try this?